When determining whether to start a business with a new business partner, we conduct a preliminary evaluation of the company by researching public information, performing interviews, and conducting on-site audits. We also utilize the new supplier evaluation checklist to assess both the basic SLQDC criteria and ESG aspects of the company.

Compliance with the aforementioned CSR Procurement Guidelines and understanding of the Green Procurement Guidelines are also included in the evaluation items, with the highest weighting assigned to ESG-related categories. We prioritize procurement from business partners with high ESG performance.

If the ESG field rating is less than 50%, the transaction will not be allowed to commence.

Weight of points for new supplier evaluation by item

| Category | Evaluation item | Weight (%) |

|---|---|---|

| ESG | Occupational health and safety, environment, compliance, export control, information security | 27% |

| General management |

Management policy, organization, financial structure, employee training, etc. |

24% |

| Production capacity | Production planning to progress management and delivery management system, procurement ability, and outsourcing management | 20% |

| Technical superiority | Development capability, cost efficiency, and maintenance ability, etc. | 16% |

| Quality |

Assurance system, on-site management, initial product management, etc. |

12% |

| Total | 100% | |

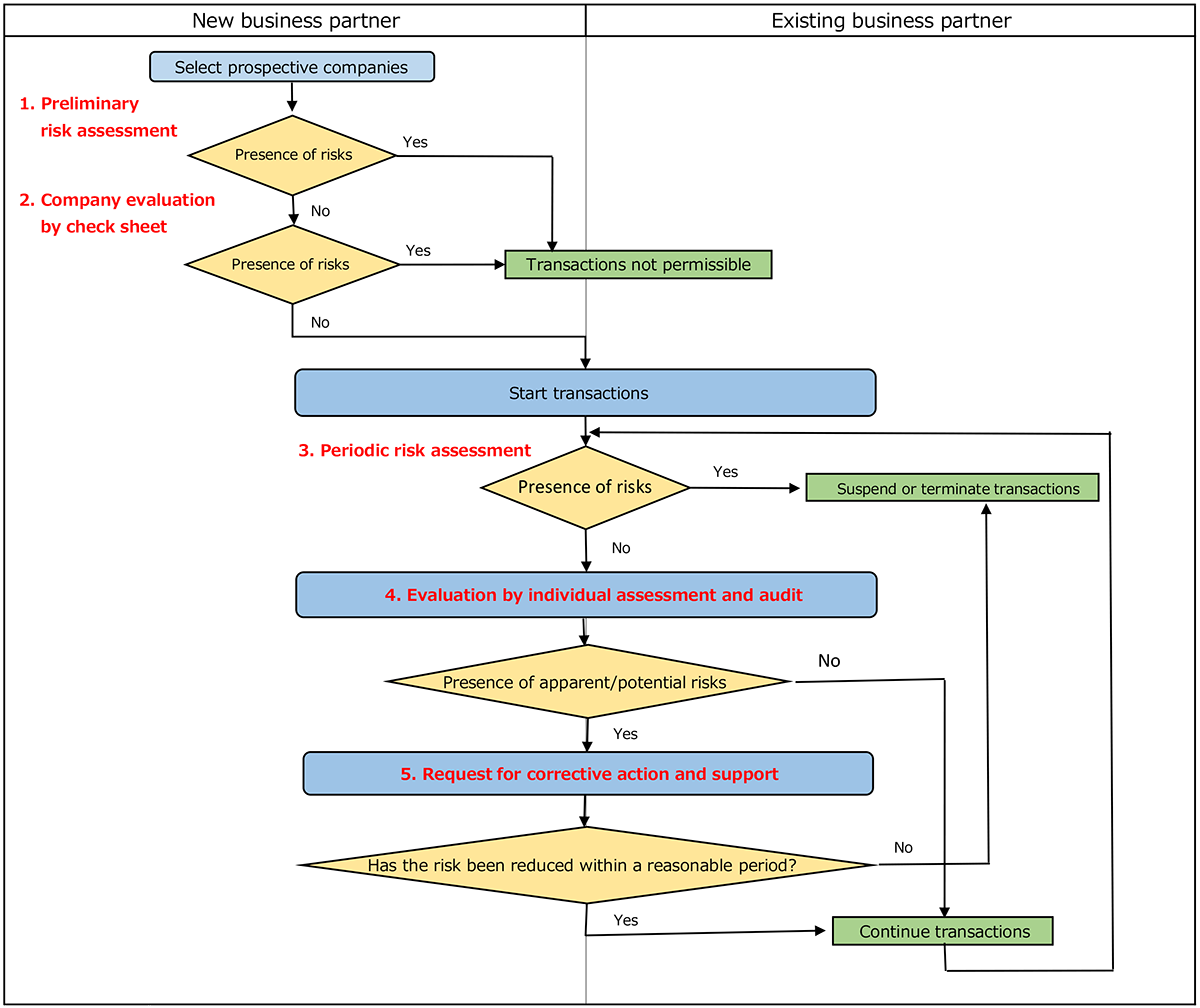

We conduct regular risk assessments using specialized external databases to screen new and existing business partners for compliance purposes. This process includes verifying whether business partners are associated with high-risk customers, regulated countries, regulated items and technologies in terms of export control, and whether they have any connections with or involvement in anti-social forces. We utilize public information and quarterly surveys to evaluate the financial and management status of potential suppliers. If companies of concern are identified, we employ credit reporting agencies to conduct further verification. In terms of CSR and ESG, we regularly verify compliance with occupational health, environmental laws and regulations, antimonopoly acts, subcontracting laws, and immigration acts through government agencies and related local authorities' websites. As part of our risk management processes for raw material procurement in the construction machinery industry, we also continue to conduct investigations on the countries of origin of conflict minerals.

Risk assessment process for business partners

Major screening and implementation status for suppliers

| Category | No | Objective | Content | Measures to check | Frequency | Target (○ to be implemented) | Implementation status in FY2023*1 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Critical suppliers (Tier 1 suppliers only) | Other Tier 1 suppliers | Number of companies | Number of companies subject to individual follow-up | Number of companies with completed or planned corrective actions | ||||||||||

| Level-1 | Level-2 | Level-3 | Japan | Overseas | ||||||||||

| Compliance | 1 | Determine companies of concern for export control. | Check whether the company falls under or is related to the list of companies of concern published by Japanese and overseas government agencies. | Chaser search in the CISTEC database. | Once a year | 〇 | 〇 | 〇 | 〇 | 〇 | 2,176 | 0 | - | |

| 2 | Determine association with anti-social forces. | Check whether the company falls under or is related to anti-social forces. | Verify through public information and specialized agencies. | Twice a year | 〇 | 〇 | 〇 | 〇 | 2,235 | 0 | - | |||

| Management | 3 | Confirm management status. | Credit investigation | Confirm management and financial status. | Public financial information and reports from private credit investigation agencies. | As needed | 〇 | 〇 | 〇 | 〇 | 〇 | 2,235 | 2 | 2 |

| 4 | Periodic survey of business conditions | Surveys on profit and loss, employment, operation rate, investment, and overall management. | Questionnaires | Quarterly | 〇 | 〇 | ||||||||

| ESG | 5 | Check for violations of labor, environment, antitrust, subcontracting, immigration, and other laws and regulations. | Search for cases of violations announced by the Labor Standards Bureau, local governments, Japan Fair Trade Commission, Immigration Bureau, etc. | Monthly | 〇 (Japan) |

〇 (Japan) |

〇 (Japan) |

〇 | 2,235 | 0 | 0 | |||

| BCP | 6 | Identify any risk of natural disasters (flooding, tsunami, landslide, etc.) based on business location. | Check hazard maps published by the Ministry of Land, Infrastructure, Transportation and Tourism, and Aqueduct. | Once every 3 years | 〇 | 〇 | 〇 | 〇 | 〇 | 1,385 (Japan) |

1 | 1 | ||

To address the potential risks identified in the supply chain, Komatsu conducts risk assessments and audits, in addition to the previously mentioned assessments, based on the importance of our business partners. These risk assessments and audits, conducted by our experts, cover individual areas of business activities. They are carried out through both desktop surveys and on-site surveys. The table below outlines the content, scope, and implementation status of these assessments and audits in FY2023.

We report apparent and potential ESG risks identified through these risk assessments and audits to our business partners, request them to develop corrective plans, and implement appropriate measures within a reasonable period. If it is difficult for the partners to address these issues independently, Komatsu provides guidance and support, with our experts assisting upon request. In FY2023, we supported 28companies. No business partners were terminated due to significant negative impacts resulting from these risk assessments, audits, and corrective actions in FY2023.

The status and results of these processes, especially concerning significant risks, are reported regularly to our management by the Procurement Division through monthly reports, including the details and progress of corrective measures.

We then incorporate the results of these assessments and audits into our purchasing policies to maintain consistency between our supplier code of conduct and purchasing activities.

In parallel with these individual corrective activities, we provide various educational and training programs and e-learning materials to support our partners in enhancing their understanding and capabilities in CSR activities.

In FY2023, we conducted human rights education for 538 employees and environmental law education for 99 partner companies.

We also recommend obtaining official certification from external third-party organizations to enhance environmental management and health and safety activities.

Activities regarding supply chain risks, including those involving our partners, are reported and reviewed twice a year by the Sustainability Committee, attended by top management including directors.

Major individual risk assessments and audits of business partners

| Category | No. | Content | Measures to check | Freuency | Target (○ to be implemented) | Implementation status in FY2023 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Critical suppliers (Tier 1 suppliers only) | Other Tier 1 suppliers | Number of companies | Number of companies with corrective action plans formulated | Completed corrective actions | |||||||||

| Level-1 | Level-2 | Level-3 | Japan | Overseas | |||||||||

| General | 1 | Strengthen interactive communication through Midori-kai activities | (1) Interaction among company leaders at regular meetings. | Meeting | Twice a year | 〇 | 〇 | 〇 | 335 | - | - | ||

| (2) Promote activities to improve productivity, energy conservation, etc. through subcommittees. | Plant visit, activity briefing, etc. | all-year | 220 | - | - | ||||||||

| Management and QCD | 2 | Corporate evaluation | Evaluate annual SLQDC and ESG performance | KPI result | Annually | 〇 | 〇 | 〇 | 335 | 0 | 0 | ||

| Evaluate the factor about the above and corporate management | KPI result, management interview | 〇 | 〇 | 99 | 0 | 0 | |||||||

| 3 | Quality audit and heat treatment audit (only for companies with safety parts and heat treatment processes) | Confirm quality assurance system and process control status. | Written survey, onsite audit, voucher check, etc. | Annually (designated companies) | 〇 | 〇 | 〇 | 〇 | 〇 | Heat treatment audit 337 |

0 | 0 | |

| 4 | Monthly operation capacity check | Confirm monthly operation capacity forecast and the way to forecast. | Written survey, management interview | Monthly | 〇 Japan |

〇 Japan |

166+α*1 | 0 | 0 | ||||

| Compliance and ESG | 5 | Compliance risk (CR) audit on important process | Identify potential risks in the areas of accounting and finance, labor management, procurement (subcontracting law), and information security. | Written survey, onsite audit, voucher check, etc. | Once every 2 years | 〇 | 4 | 2 | 2 | ||||

| 6 | Survey on the employment status of overseas workers | Survey on compliance with laws and regulations regarding employment of overseas workers (including trainees). | Questionnaire and interview | Annually | 〇 | 〇 | - | - | - | ||||

| 7 | Occupational health and safety level assessment (including compliance check) | Confirm organizational structure to promote occupational safety and health activities, compliance with labor-related laws and regulations, and evaluation of activities. | Onsite audit such as safety patrol, interview with management and safety managers, etc. | Twice a year | 〇 | 〇 | 99 | 15 | 15 | ||||

| 8 | Promote acquisition of environmental management system (EMS) and environmental education | Mandate acquisition of third-party certification for environmental management | Written survey, onsite audit, Interview with management and environmental officers, etc. | Annually | 〇 | 〇 | 〇 EMS |

99 | 0 | 0 | |||

| Implemate education on the latest environmental laws and regulations | Online education | Annually | 〇 | 〇 | 99 | 11 | 11 | ||||||

| 9 | CSR SAQ survey | Self-assessment of overall CSR using a checklist. | Questionnaire and interview | Once every 3 years | 〇 | 〇 | 〇 | - | - | - | |||

| 10 | Risk survey on human rights | Self-assessment focused on human rights and occupational health and safety using a checklist. | Once every 2 years | 〇 | 〇 | 〇 | - | - | - | ||||

Examples of corrective action support for business partners

| Category | No. | Major support | Content |

|---|---|---|---|

| Management | 1 | Cash management support | Advance payment, cash payment, etc. |

| Purchase of excess inventory, advanced ordering & receiving, etc. | |||

| Purchase of production equipment, lending, etc. | |||

| 2 | Human resource support | Dispatch of managers and technical instructors on secondment, acceptance of training at our company, etc. | |

| 3 | Provision of education and training programs | For managers and general employees |