In the areas afflicted by anti-personnel landmines, Komatsu has engaged in activities to support community development throughout the process from demining to reconstruction. Utilizing Komatsu’s demining machines and construction equipment, developed by combining its technical expertise, knowledge and experience in manufacturing, Komatsu started its project in Cambodia in 2008 partnering with the authorized NPO "Japan Mine Action Service" (JMAS) and another project in Laos in 2016.

From a land contaminated with dangerous landmines to a land where people can live in safety and security, and further on to a land with added value through the construction of roads and elementary schools. Komatsu will continue to promote activities that contribute to the independent reconstruction of the entire community by providing support through construction equipment, which is our core business.

Clear landmines from the vast tracts of land. In the aftermath of war and civil war, landmines and unexploded ordinance remain in many areas in Cambodia. Still today citizens continue to suffer severe injuries and even death from landmines. Buried in the vast tracts of land near the Thai border in the northwestern part of the country are countless anti-personnel landmines, preventing restoration and development. In order for people to return to the abandoned farmlands and deserted villages, our clearing of the landmines and making the land safe to live and walk upon must be our first task.

By restoring farmland and roads, people regain their livelihoods. The Project does not end with the clearing of landmines. That step only restores the land’s ability to fulfill its role in the development of farmlands or construction of roads. The two main crops of Cambodia are rice and cassava. For efficient cultivation and harvesting, land intended for rice paddy-use needs to have the unevenness of the ground and other irregularities eliminated. The result of using bulldozers equipped with ICT to level the land and prepare it for rice paddy cultivation and harvesting is a nearly doubling of yield. In addition, irrigation canals and reservoirs have been created to alleviate water shortages. Previously farming in the dry season was not possible. Now more and more farmers are enjoying access to water from irrigation canals for their crops. Moreover, construction of a network of new and improved roads connects farmers not only with towns and the region but also with vital lifelines. The impact of all these improvements is large. People living in villages are choosing to stay. Those who left to find work in other countries are returning to build prosperous lives on the reborn land. Soon the newly constructed roads will be busy with people coming and going between home and villages alive with hope and vitality.

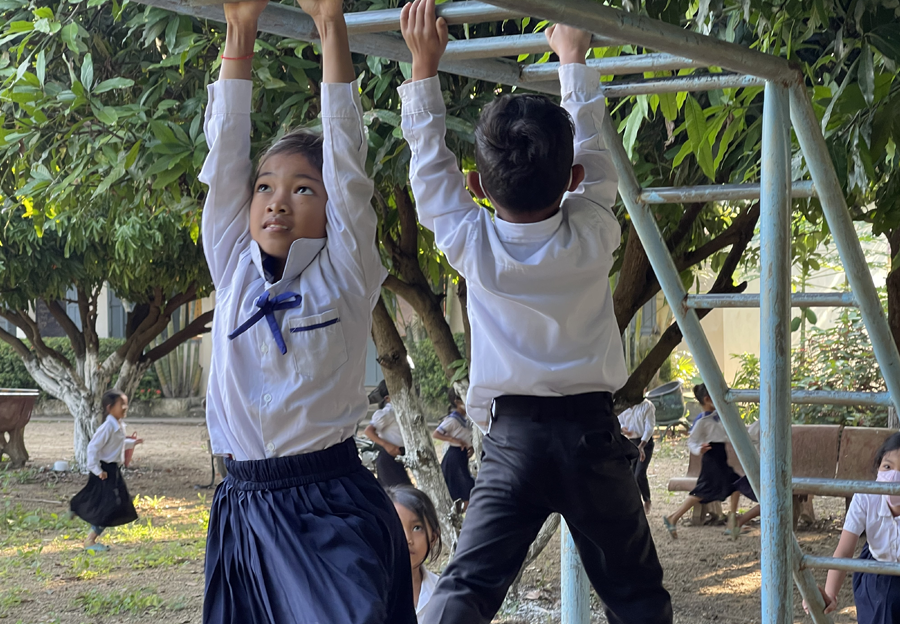

"Learning is creating your future". That is what the principal of a local elementary school said to his students. There was a child who gave up going to school because the school in the minefield was far away. There were also schools where the school buildings were so dilapidated that it was difficult to study. It has been more than ten years since we started building elementary schools. Some children have graduated from the first and second schools and are now college students. A small bud seemed to open into a large flower. People gather in places that used to be minefields, schools are built, and students learn. Each person will find their own dream. That's why children's smiles shine so brightly.

Komatsu has been involved in the construction of a total of 10 elementary schools in Cambodia, as of April 2025. All of these elementary schools were built on former minefields, and many of the students are from economically disadvantaged families. However, after graduating from elementary school, some students have begun to pursue higher education. Therefore, Komatsu launched a new scholarship program in FY2022 for students graduated from these Komatsu-built elementary schools. In FY2024, 21 students utilized the program, and in FY2025, 25 students are benefiting from it.

In May 2024, a study tour was conducted to visit demining sites and reconstruction areas, targeting Komatsu Group employees and their families. The tour, which focused mainly on employee-participation CSR activities, welcomed a total of 45 employees and their families. In addition to observing Komatsu construction equipment at work in minefields, agricultural lands, and infrastructure development sites, the group visited an elementary school built with Komatsu's support. At the schools, participants engaged in activities such as painting, repairing desks, and interacting with students through science experiments and a tug-of-war game.

We started support of unexploded ordnance disposal activities in 2016 in Xiangkhouang province, northern Laos.

In Laos, more than 30% of the land is contaminated with unexploded ordnances, mostly cluster munitions, which harm children and farmers every year. Komatsu plays its part by offering the necessary machines free of charge for the mechanized operations jointly conducted by UXO-LAO (a Lao unexploded ordnance disposal squad) and the Japan Mine Action Service (JMAS), alongside engineering support for the machines it provides.

As part of the "Visiting Lecture" initiative, Komatsu employees visit schools in Japan to introduce the activities of the demining project to a wide range of young people, from elementary school students to university students. As of March 2025, we have conducted approximately 140 lectures, reaching about 12,000 students, including those held online.

Feedback from high school students included comments like, "I learned that Komatsu, a construction machinery company, is extending its support to regions such as Cambodia by collaborating with the government and JMAS. I realized that many fields hold great potential. Working with various people can expand possibilities in many directions, which is something I want to keep in mind moving forward," and "Even when we talk about 'social contribution' or 'international contribution,' I realized there are countless issues and many organizations and people striving to solve these issues. I have a big dream of being involved in international contribution in the future, and I now understand that there are many paths besides the one I am currently thinking of pursuing."

Komatsu will continue to provide visiting lectures to inspire children, who will lead the future, to think about world peace, their future, and their lives.

| Year | Activity (international treaties and activities of the Japanese government are underlined) |

|---|---|

| 1998 | Komatsu develops old timber removal machine for demining in Cambodia |

| 1999 | Entry into force of the Ottawa Treaty (the Mine Ban Convention) |

| 2002 | The Japanese government has announced to exempt demining equipment for anti-personnel landmine from the Three Principles on Arms Exports. |

| 2003 | Development of demining equipment for anti-personnel landmine funded by the Ministry of Economy, Trade and Industry and NEDO (Figure (1) below) |

| 2004 | With support from the Ministry of Foreign Affairs of Japan, Komatsu conducts on-site testing in Afghanistan |

| 2006 | With support from the Ministry of Foreign Affairs of Japan, Komatsu conducts on-site testing in Cambodia |

| 2007 | The first demining equipment for anti-personnel landmine introduced in Afghanistan (Japanese government ODA) |

| 2008 | Komatsu begins the Cambodia reconstruction project together with the JMAS, NPO |

| 2009 | Komatsu begins the Angola reconstruction project together with the JMAS, NPO |

| 2010 | Entry into force of the Oslo Treaty (the treaty banning Cluster Munitions) |

| 2015 | Komatsu develops demining equipment for anti-personnel landmine (Figure (2) below) |

| 2016 | Komatsu begins the Laos reconstruction project together with the JMAS, NPO |

| 2017 | Komatsu completes the Angola reconstruction project |

| 2019 | Komatsu constructs 9th elementary school in Cambodia, and the 1st in Laos. |

| 2020 | Komatsu begins the agriculture CSR project in Cambodia |

| 2022 | Komatsu constructs 10th elementary school in Cambodia |

| 2022 | Start scholarships to support university enrollment for graduates of elementary schools built in Cambodia |

| 2025 | Start scholarships to students enrolled in the Heavy Equipment Maintenance Department at CFPT-SJ in Senegal |

| 2025 | Demining equipment for anti-personnel landmine introduced in Senegal (Japanese government ODA) |