The main bulk of CO2 emissions produced throughout the lifecycle of our construction equipment is centered on product operation, during which approximately 80 to 90% of emissions are produced. We have acknowledged this fact, and are working to reduce these operational emissions through three different initiatives: “DANTOTSU Products”, “DANTOTSU Service”, and “DANTOTSU Solutions”.

We provide products which have been designed to operate with great fuel efficiency while reducing gross CO2 emissions. Komatsu pioneered the creation and introduction of the hybrid hydraulic excavator, marked as the first of its kind to be introduced into the market.

These hybrid construction machines have been certified by the Ministry of Land, Infrastructure, Transport and Tourism of Japan as a “Low Carbon Type Construction Equipment.”

As of April 2023, a total of 16 of our hybrid models have received such certification, such as the HB215-3, HB205-3, HB335-3, and HB365-3.

In addition to this, another 24 of our product models (including the bulldozer D71PX-24, the hydraulic excavator PC78US-11, the wheel loader WA150-8) have been certified to meet the Ministry of Land, Infrastructure, Transport and Tourism's “Construction Machines Fulfilling Fuel Economy Standards” signifying these products as construction equipment with great fuel efficiency.

The Komatsu Tracking System “Komtrax” is a system developed by Komatsu that automatically gathers the operational information/health information of our construction vehicles that operate all over the world, making it possible to then monitor/manage/analyze the vehicles remotely. Information with regards to operation times, fuel consumption, and other such relevant data is communicated to our customers via the internet, which is then analyzed to create opportunities for improvement. This enhanced operational efficiency helps to reduce fuel consumption, which results in a reduction in overall CO2 emissions.

In 2013, Komatsu introduced the world’s first automatic blade control ICT bulldozer, D61PXi-23, to the North American, European, and Japanese markets. Following this, in 2014, Komatsu developed and released a hydraulic excavator with semiautomatic control functions (PC210LCi-10 for North America and Europe, and PC200i-10 for Japan). Preliminary calculations based on in-house testing were promising, with construction data for ICT hydraulic excavators showing that fore-slope shaping work using the PC200i-10 resulted in an approximate reduction of 30% in fuel consumption. In addition, the same testing showed that ICT bulldozers (like the D61DXi-23) used in land preparation work resulted in an approximate reduction of 25% in fuel consumption. Our testing with hydraulic excavators also showcased a significant decrease in CO2 emissions.

To consolidate our efforts in this sector, Komatsu is implementing “Smart Construction”, a system that uses ICT-type construction machines alongside drones and 3D scanners to take real-time topography measurements. This initiative helps showcase the efficiency of our machines by recording progress in construction sites and other relevant performance indicators.

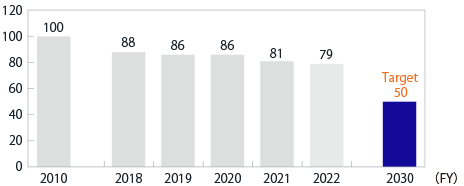

Komatsu has set the target of reducing the CO2 emissions from the operation of products (such as construction, mine, and forestry equipment) by 50% by FY2030 (compared to FY2010).

To evaluate progress toward this goal, we compared the performance of the current year’s products to the products of the reference year (FY2010) and estimated CO2 reductions through the improvement of fuel consumption and work efficiency. The products of FY2022 achieved a CO2 reduction of 21%, compared to the reference year.

CO2 emission index for product operationsIndependent Practitioner's Assurance

To achieve carbon neutrality, in December 2022, Komatsu launched the FE25G-2 and FE30G-2 for the Japanese market. These models are equipped with high-capacity lithium-ion batteries in the FE Series of 2.5-ton and 3.0-ton class electric forklifts that help reduce CO2 emissions.

The new models inherit the FE Series truck dimensions and other features (FE25-2 and FE30-2) while adopting high-capacity, fast-charging lithium-ion batteries and the newly-developed stationary fast chargers. These batteries expand the scope of application of electric forklifts. This makes them suitable for sites where extended operation times (with no recharging time available) are required and/or heavy attachments are used in heavy-duty applications; domains previously served only by engine-powered forklift trucks. By increasing battery capacity by 35% (compared with the FE25-2) for 2.5-ton models and 22% (compared with the FE30-2) for 3.0-ton models, operating times have been extended by approximately 20-30% (*1). Additionally, the charging time to reach 100% charge has been reduced from more than 8 hours to 1 hour and 50 minutes, about a quarter of the charging time of Komatsu's conventional electric forklift trucks (*2). A fast battery replenishment feature enables recharging during downtime. Furthermore, the optional dual fast charger enables full recharging in less than one hour, contributing to continuous operation at sites where finding time for recharging equipment is challenging.

By expanding the FE series lineup, we will further increase the number of sites where electric forklifts are operated and help to reduce our environmental impact and achieve carbon neutrality.

Komatsu introduced a new 90-ton-class large hydraulic excavator, model PC950-11 (bucket capacity: 4.0 m3), to the market in July 2022. The machine is equipped with an electronic control closed-loop swing system, newly developed by Komatsu, which regenerates energy during swing deceleration using hydraulic pressure, thereby realizing fuel savings. Additionally, a high-efficiency oil flow recycle system has been introduced for arm IN and boom RAISE functions to achieve both higher equipment speed and reduced fuel consumption. The hydraulic system is electronically controlled to optimize the control of the hydraulic equipment per the operating conditions of the vehicle body, achieving good operability and significantly reducing hydraulic losses. The renewal of the hydraulic system and the installation of a new engine have resulted in a 40% improvement in the fuel efficiency of the entire vehicle body compared with the conventional PC850-8E0. All of this machine’s major components, such as control valves, main pumps, swing motors, traveling motors, and hydraulic cylinders, are developed and manufactured in-house. The hydraulic equipment pursues "quality and reliability," the basis of Komatsu's management policy, and thus reduces machine downtime and helps customers improve productivity at their sites.

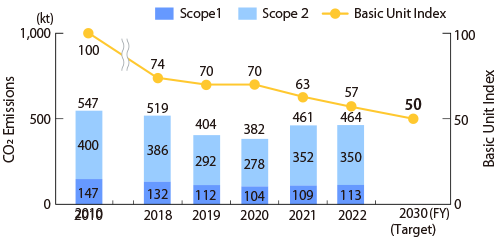

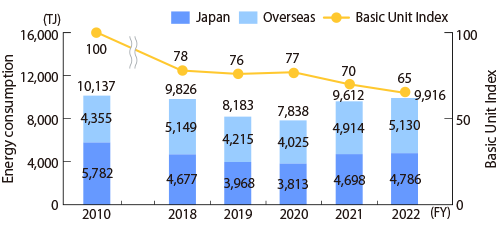

As a part of our efforts to mitigate climate change, Komatsu promotes activities to reduce the amount of CO2 emissions per unit, using CO2 emissions per unit of manufacturing value as our main indicator for the amount of electricity, gas, oil and other types of energy used in research/development at our offices and in manufacturing operations.

In FY2022, CO2 emissions from production activities increased both in Japan and overseas due to the expansion of production volume. However, new photovoltaic and bioenergy facilities, green electricity purchases overseas, and energy-saving activities, mainly at plants with high loads (such as those that perform casting, forging, heat treatment, and machining processes) have enabled a 6% reduction in the CO2 emissions basic unit per internal manufacturing value over the previous year’s figure, which indicates a 43% reduction compared with FY2010.

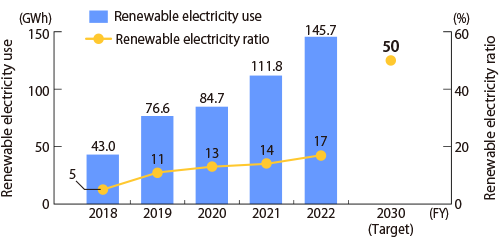

We also increased the proportion of our renewable electricity use to 17%.

We will continue to actively promote the introduction of new production technologies and improvement activities to reduce our CO2 emissions basic unit.

| Item | FY2021 | FY2022 | Target of FY2030 |

|---|---|---|---|

| CO2 emissions basic unit (compared to FY2010) | 63 | 57 | 50 |

| The rate of renewable energy use | 14% | 17% | 50% |

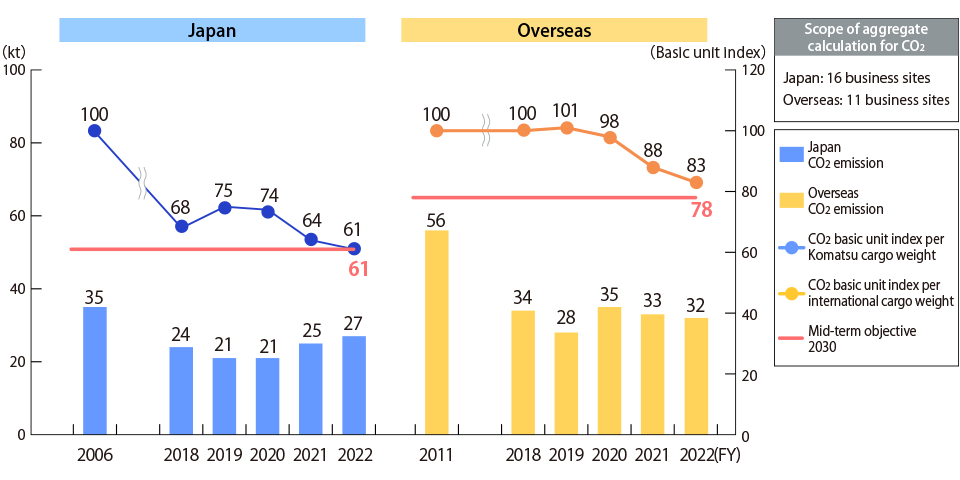

Japan

Overseas

CO2 emissionsIndependent Practitioner's Assurance

Note: The breakdown of emissions was changed to Scope 1 and 2.

The amount and ratio of renewable electricityIndependent Practitioner's Assurance

Note: Partially revised as a result of revisions to past data.

Energy consumption

Independent Practitioner's Assurance

In 2022, Komatsu completed construction of a new corporate campus in Milwaukee, Wisconsin, U.S., called South Harbor. The campus, which includes an office building and a manufacturing facility, engages in the manufacture and sale of surface mining equipment used around the globe. South Harbor was designed with a focus on reducing energy and water consumption and creating areas of biodiversity. The campus’s office building has been certified LEED Gold, a globally recognized symbol of excellence in green building. South Harbor incorporates many innovative features designed to help the company reach its goal of reducing energy consumption by 75% compared to usage at legacy Milwaukee facilities. Solar panel arrays and wind spires are used to help power the buildings and parking structure. Other features include LED lights with occupancy sensors, and daylight harvesting technology that automatically adjusts interior lights based on the amount of sunlight entering the buildings’ windows. For the remaining energy consumed, renewable energy credits are purchased equal to 100% of electricity used. To reduce water consumption, the campus installed a rainwater collection system for non-potable reuse in facility lavatories. All manufacturing processes use closed loop water cooling systems. These improvements and others will help Komatsu reach its goal of reducing the amount of water consumed by approximately 80% compared to legacy facility usage. Biodiversity is encouraged on the campus grounds with planting hardy perennial varieties that provide natural habitats and require no watering. The environmental advancements implemented at South Harbor will have a significant benefit in reducing energy consumption, reducing water consumption and increasing biodiversity throughout the site.

(Basic unit of CO2 emissions per cargo weight)

In domestic transportation, we have focused on reducing transportation distances through the effective use of Kanazawa and Hitachinaka ports adjacent to manufacturing plants, improving long-distance and overland transportation by actively utilizing coastal vessels and railways (modal shift), and improving the loading ratio. Although the increase in production volume in FY2022 led to an increase in transportation volume, the CO2 emissions basic unit index (per cargo weight) for transportation improved compared to the previous year both in Japan and overseas, with domestic improving by 3 points and overseas by 5 points in the basic unit index.

We will continue our efforts to reduce CO2 emissions by promoting more efficient transportation.

CO2 emissions in transportIndependent Practitioner's Assurance

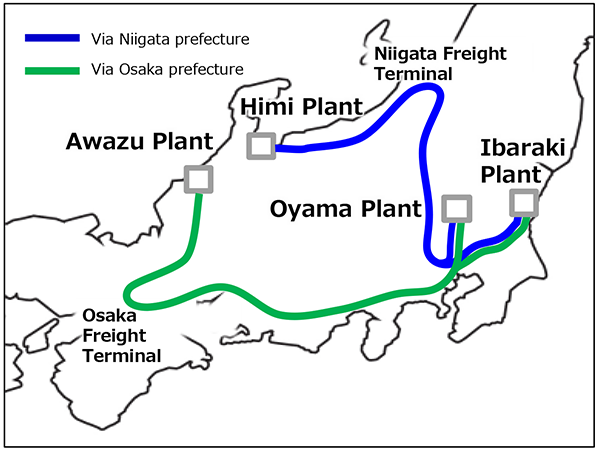

Komatsu is promoting a modal shift to reduce CO2 emissions generated by domestic transportation. In FY2022, we focused on improving transportation between our plants in the Hokuriku and Kanto regions. Specifically, we switched from conventional overland transportation by truck to rail transportation using JR containers to transport components and parts from the Hokuriku region (Himi Plant and Awazu Plant) to the Kanto region (Oyama Plant and Ibaraki Plant). As a result of this improvement, we have reduced CO2 emissions by 150 tons per year.

Japanese rail transportation route