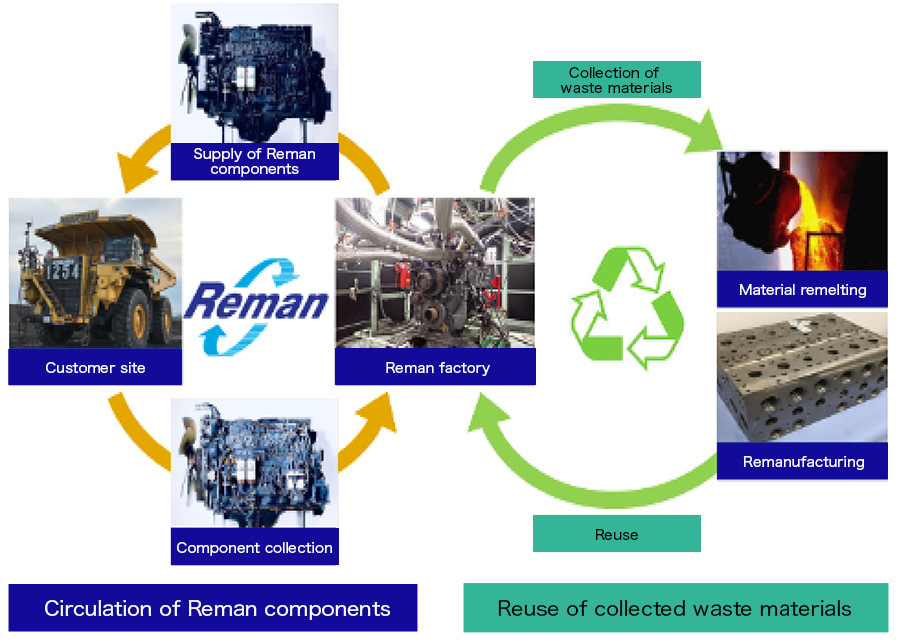

"Reman" is short for "Remanufacturing," meaning regeneration.

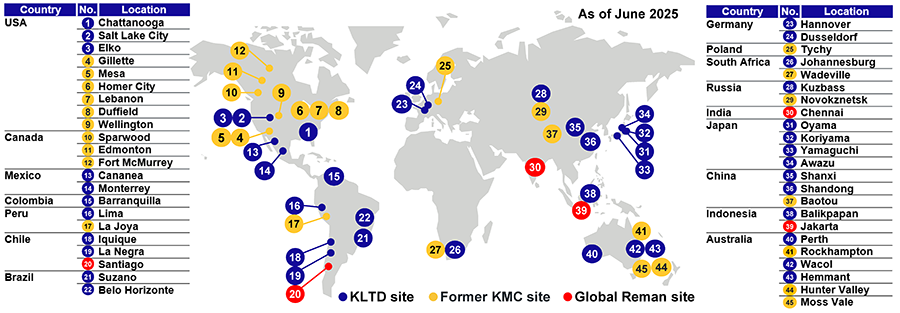

This business involves collecting components from construction and mining equipment that have been in operation for extended periods. These components are then remanufactured at Reman plants to restore them to a like-new condition and are provided to customers in line with overhaul timing (disassembly, inspection, and repair). Mining equipment, which is the primary focus of the Reman business, is typically used for 10 to 15 years, and multiple overhauls—including 2 to 3 component replacements—are essential throughout its lifecycle (total operating hours).

Reman products offer the same level of quality as new components, but at a lower cost. Komatsu's Reman business continues to grow as a resource-circulating business that contributes to environmental conservation while also helping customers reduce their lifecycle costs.

The Reman business model leverages Komatsu’s strength in developing and manufacturing key components such as engines, transmissions, and motors in-house. This enables components to be remanufactured according to the original design and production specifications, resulting in Reman products that are competitive in terms of quality, lead time, and cost. In addition, information such as component durability obtained during disassembly is fed back to the development division to support product development, quality improvement, and enhanced serviceability.

The Reman business creates value not only for customers, but also for the global environment, distributors, and Komatsu.

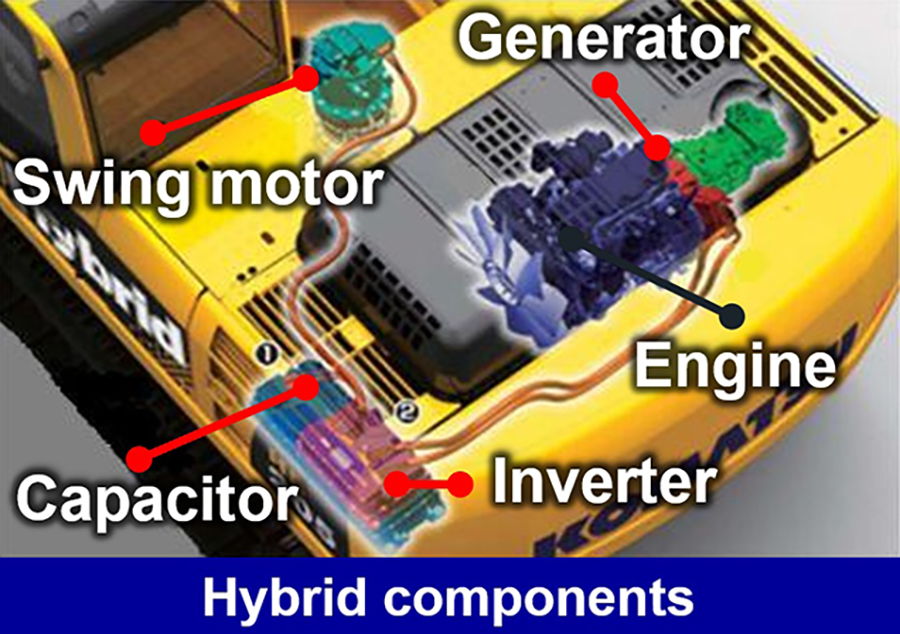

Komatsu has been working to reduce CO2 emissions from its products by developing highly fuel-efficient equipment such as hybrid hydraulic excavators and diesel-electric vehicles. Along with the increase in the number of these units in operation, Komatsu started remanufacturing key components (capacitors and inverters) for hybrid hydraulic excavators in November 2023 as part of its remanufacturing business. This initiative now enables remanufacturing support for almost all key components developed and produced by Komatsu, including some products deployed only in limited regions.

Looking ahead, in line with the electrification of construction machinery to achieve carbon neutrality, Komatsu is also expanding its remanufacturing menu to cover batteries and other related components. Through collaboration with various partners, Komatsu aims to accumulate technological expertise and explore new opportunities in the remanufacturing business.

Komatsu is working on the conservation and effective use of limited resources by reusing critical materials used in products, etc.

An increasing number of diesel engines, which are used in construction machines, are now equipped with exhaust gas processing devices to reduce the density of NOx (nitrogen oxide) and PM (particulate matter) in exhaust gases. The exhaust gas processing devices use noble metals as a catalyst to reduce the density of NOx and PM. To effectively use these resources, Oyama Plant in Japan, for example, collects the exhaust gas processing devices of construction machines that have been replaced and recycles the noble metals in them. They are also recycling other critical materials to make them reusable, ensuring their effective use and aiming to reduce the consumption of new critical materials.

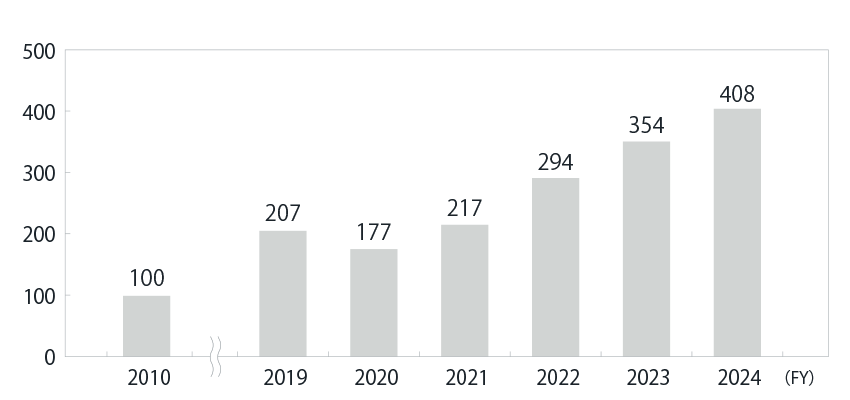

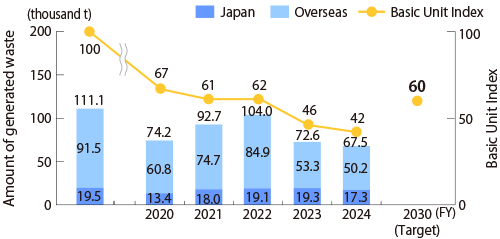

Komatsu promotes initiatives to reduce waste emissions while also advancing “zero emission” activities aimed at recycling and effectively utilizing the waste we generate.

At our domestic production sites, we are working on converting waste plastics into valuable resources, reducing wood waste by improving transport packaging, and reusing packaging materials. Overseas, we are also actively promoting recycling by separating waste. In FY2024, we promoted the effective use of sand used in casting processes and worked to reduce plastic waste, including packaging materials. These efforts significantly reduced total waste emissions. As a result, the Intensity of waste emissions was reduced by 58% compared to FY2010.

| Item | FY2023 | FY2024 | Target of FY2030 |

|---|---|---|---|

| Index of waste generated per unit (Reference year: 2010) |

46 | 42 | 60 |

《Japan》

《Overseas》

Amount of generated wasteIndependent Practitioner's Assurance

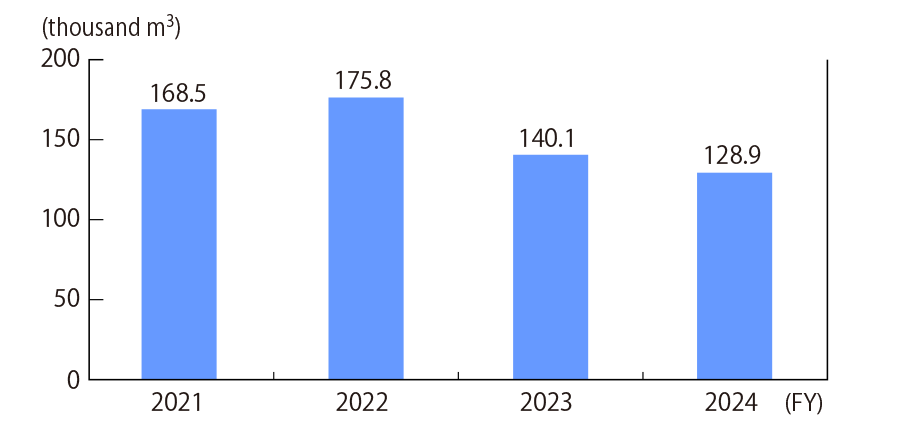

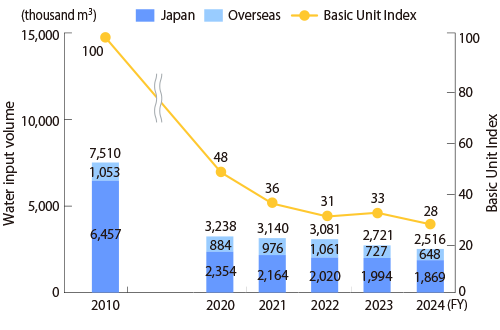

Given that our plants in the Hokuriku area of Japan use particularly large amounts of water, Komatsu continues to optimize water use for snow melting purposes during winter, while improving water efficiency in production processes—such as recycling cooling water and converting water-cooled systems to air-cooled ones—in order to reduce the volume of newly introduced water.

In FY2024, we significantly reduced the total water input compared to the previous year, achieving a 72% reduction in the Intensity compared to FY2010.

| Item | FY2023 | FY2024 | Target of FY2030 |

|---|---|---|---|

| Index of water input volume per unit (Reference year: 2010) |

33 | 28 | 30 |

《Japan》

《Overseas》

Water input volumeIndependent Practitioner's Assurance

At Komatsu Indonesia (KI), we are committed to reducing environmental impact and preserving the environment through all of our business activities.

One of our key initiatives is water conservation.

As part of this effort, Komatsu Indonesia began recycling water in 2013 by installing an ultrafiltration (UF) filter at our wastewater treatment facility to remove even fine particles.

The treated and recovered water is reused for both domestic and industrial purposes.

To further increase the volume of recycled water, we introduced a rainwater harvesting system.

This system collects rainwater in storage tanks, purifies it, and produces clean water for use.

As a result of these efforts, over the past 10 years, we have improved our water recycling rate to approximately 50% of total water input.

We have also continued to expand our recycling capacity by increasing the UF filter’s capacity and installing lamella clarifiers to enhance the efficiency of solid-liquid separation.

These efforts have contributed to raising our water recycling rate to 70%.

More recently, we introduced a system that directly uses water from on-site ponds for irrigating green spaces, significantly reducing overall water consumption.

Komatsu Indonesia remains committed to these initiatives and to continuous improvement. We regard efficient water use as a top priority and will continue to advance our water conservation activities.

Total Water Consumption (KI)