Komatsu complies with national and local laws and regulations and ensures that it periodically reports and maintains measurement results.

In FY2022, there were three violations of environmental regulations in Japan, and each of them minor. No fines are imposed and they have all been resolved.

At overseas sites, there were exceedances of effluent standards in North Europe (KFAB) and mismanagement of hazardous waste in Latin America (KCH). A fine of US$1,500 was imposed in Latin America; however, they have since been resolved.

Komatsu has established guidelines for testing soil and groundwater, inspects any business unit that is scheduled to be sold, closed, or removed pursuant to laws and regulations, and takes purification measures upon confirmation by local authorities if contamination is discovered.

We voluntarily investigate business units in operation in order to test for contamination stemming from VOCs in cleaning solvents, etc. used in the past.

We have been surveying soil and groundwater for VOC contamination at domestic business units since 2005, and have implemented countermeasures at any sites that have been found to be contaminated. We use methods that facilitate the cleaning process in the shortest period of time possible.

We will continue to thoroughly clean-up and regularly monitor groundwater at site boundaries to ensure that there is no outflow of groundwater that has exceeded the standard outside the premises.

Komatsu stores and disposes of PCB-containing waste (such as transformers and fluorescent stabilizers) in accordance with the "Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes" and the "Waste Management and Public Cleansing Law".

Appropriate measures were taken for high-concentration PCB waste by the disposal deadline (end of March 2023).

We intend to continue our appropriate treatment of PCB waste, including low-concentration PCB waste, according to our plan.

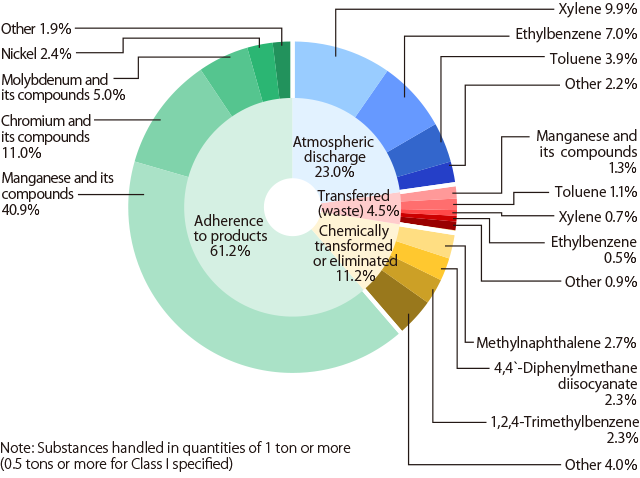

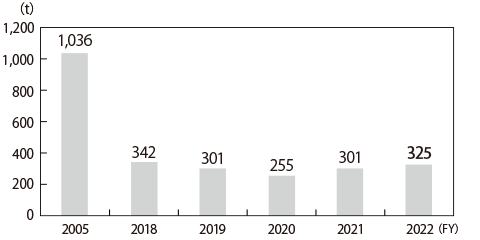

In FY2022, the number of PRTR* substances with a handling volume of 1 ton or more (0.5 tons or more for Class I Designated Chemical Substances) was 25, unchanged from the previous fiscal year.

The PRTR substances xylene, ethyl benzene and toluene account for approximately 90% of the emissions from Komatsu and Komatsu Group production sites. Most of these emissions are released into the atmosphere.

In FY2022, each business site made progress in switching to paint thinner, which contains less PRTR Class 1 substances, but emissions increased with the rise in production volume.

In FY2023, we will continue to make efforts to switch to paints containing less PRTR Class 1 substances, introduce high solids thinners and paints, improve coating efficiency, reduce coating film thickness, and recycle paint thinner.

Komatsu Group Manufacturing Facilities in JapanIndependent Practitioner's Assurance

Komatsu Group Manufacturing Facilities in JapanIndependent Practitioner's Assurance

NOTE: Substances handled in quantities 1 ton or more (0.5 tons or more for Class 1 specified)

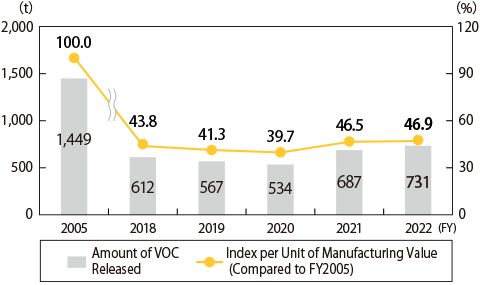

The majority of VOC emissions are from VOCs contained in paint such as xylene and ethyl benzene.

Although emissions in FY2022 increased slightly compared to the previous year due to the rise in production volume, we successfully maintained a 50% reduction in the amount of VOC emissions per unit of manufacturing value (compared to FY2005).

Komatsu Group Manufacturing Facilities in JapanIndependent Practitioner's Assurance

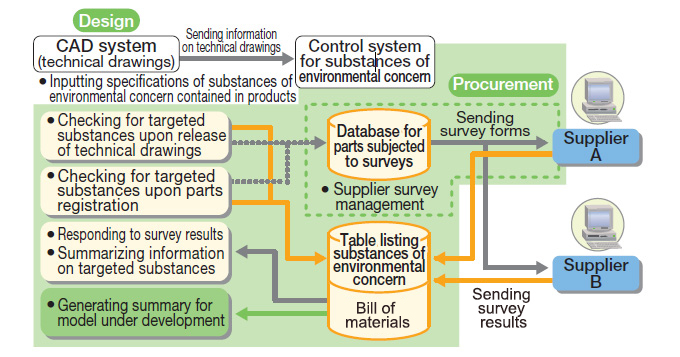

Komatsu is aware of the harmful environmental impacts that certain materials possess, and has made continuous efforts from an early stage to reduce the use of a number of such substances. These included asbestos, lead, and other such items. In FY 1999, we created our own list of banned and limited-use substances (Refer to “Substances of Environmental Concern Banned or to Be Reduced for Use in Products”), which was based in part on Japanese legislation (Japanese Law Concerning the Examination and Regulation of Manufacture of Chemical Substances Control) that banned a number of chemical materials as well as regulatory measures in other countries.

We have also implemented more stringent measures in the control of substances that raise environmental concerns. In compliance with REACH*1 and SCIP*2, we began revisions of our FY 1999 listing of banned and limited-use substances. We have also collaborated with suppliers to create a regulatory system that strengthens control of potentially harmful materials being used for production. We have rolled this system out in Japan and Europe, with plans to continue implementation in other areas of operation.

Through the use of this system, we identify SVHC (substances of very high concern) in not only vehicles for export to the EU or produced at local EU companies, but also in vehicles currently in production and in newly developed vehicles. Furthermore, we also regularly check for new SVHCs to be added to the list.

As of 2023, there are 233 SVHCs registered, with the list being revised every six months. We expect this number to increase to about 1,500 in the future. We have also devised a workflow to monitor control of these substances.

| Rank | Number | Chemical Substance |

|---|---|---|

| Banned |

21 |

|

| To be reduced (Subject to limited use) |

15 |

|

| Substances of Very High Concern (SVHC) under EU REACH Regulations |

(233)*5 |

Komatsu controls the use of the following substances, which might be used in Komatsu products.

|

We are reducing and ending our use of substances of environmental concern. One of our efforts to achieve this is our plan to replace components containing specific phthalate esters with alternatives by 2024.

To reduce the NOx (nitrogen oxide) and PM (particulate matter) contained in the exhaust gases of diesel engines, which are used in construction equipment and other machinery, new emission control regulations have been established, and we have been developing products that emit cleaner exhaust gasses. About 78% of the construction machinery manufactured in FY2022 complies with regulations equal to or more stringent than U.S. Tier 3 and EU Stage IIIA regulations. As a result, the average NOx and PM emitted by the construction equipment products produced by Komatsu are shown below:

Average emission value of NOx and PMIndependent Practitioner's Assurance

| FY2020 | FY2021 | FY2022 | |

|---|---|---|---|

| NOx(g/kWh) | 3.1 | 3.5 | 3.5 |

| PM(g/kWh) | 0.16 | 0.18 | 0.17 |

Due to climate change, population growth and other phenomena brought by global warming, risks of river flooding, droughts, water shortages and other water-related problems have surfaced all over the world and are becoming more serious every year.

The Komatsu Group believes that everyone has the right to access to safe and sanitary water, and we respect it as one of the most important rights. We also fully understands that we depend on that water and our business operations are influenced by and exert influence on the quantity and quality of that water.

Therefore, we engage in production activities that minimize environmental impact, provide good products and services and take appropriate actions to mitigate water-related risks in an effort to conserve local water resources and ensure that the water stays safe. It is our goal to promote these activities at All Komatsu and lead to the conservation of the global environment.

Through these initiatives, we contribute to the SDGs, a set of common goals for the world.

Based on the Komatsu Earth Environment Charter, the Komatsu Group has promoted the reduction of water usage and recycling and has carried out activities, mainly for the protection of water quality. In 2020, we conducted a water-related risk survey at our 76 main offices in Japan and other countries, irrespective of whether they handle production. In this survey, we conducted (1) versatile and objective identifications of water-related risks using WRI Aqueduct, and (2) subjective awareness surveys of water-related risks that Komatsu considers to be important. Combining these two surveys, we expanded the scope of the water-related risk survey and increased its accuracy. The water-related risk survey showed that Komatsu Group had some areas facing risks of disasters such as heavy rains, river flooding and tsunami (including risk awareness to the supply chain) .

Going forward, we will conduct a water-related risk survey on a regular basis to keep updated on the water-related issues of the Komatsu Group.

Using WRI Aqueduct, we surveyed 34 main production bases of the Komatsu Group about water stress risks in the water resource usage required for their production activities, such as clean water (tap water/city water), industrial water (clean water for industrial use), and well water. We corrected the results from WRI Aqueduct based on unique evaluations of the specific business locations.

As of 2020, the business locations whose water stress risks were rated as high or middle-to-high account for 9% of our water usage. While approximately 64% of the water used by Komatsu as a whole was well water, we found that all of the water used in the business locations with high or middle-to-high water stress risks was clean water and that water usage reduction and water recycling are important for securing water resources in these areas.

The table below presents the results of the water risk assessment of production sites aggregated by personnel ratio.

| Survey cover ratio |

100% |

|---|---|

| Water stress high risk ratio |

8% |

| Flood high risk ratio |

8% |

We will effectively use these survey results for activities we have conventionally engaged in, such as the promotion of water usage (input volume) reduction and recycling, adaptation to physical risks of heavy rain and flood, aiming to reduce the water-related risks the Komatsu Group is exposed to. In addition, when planning the construction of a new business base or the transfer of a base, we will survey water stress in that area to identify the risk level.

We have initiated the construction of multiple safety measures against the risks imposed by heavy rain. These include the building of three reservoirs (capable of holding up to an hour's worth of 100mm/h rainfall), installation of heavy rainfall water pipes, the construction of underground reservoirs, and the widening of rainwater drainage ways. In addition to this, we have installed water block walls and stop bars to prevent water from flowing outside of the premises.

Current Status of Reservoirs:

KIPL: Flooding from rivers may enter the parts warehouse and remanufacturing store during heavy rainfall. The following measures have been taken to prevent the entry of river flood water:

KRA: This area receives heavy rainfall and is located in a canyon, so large amounts of water may enter the site. The following measures have been taken to prevent the entry of water:

Our water-related risk survey was conducted at the operations of one of our main supply chain companies (Midori-kai), and Midori-kai has made collaborative efforts in our water-related risk reduction activities since FY2017.

Komatsu has been conducting planned compliance and risk audits (CR audits) since FY 2007 for risk prevention at overseas group companies with the support of environmental managers at mother plants in Japan.

In FY2022, we conducted audits in Southeast Asia and the United States. We conducted remote audits in Southeast Asia, where the time difference is minor, and the effects of the new coronavirus were not yet completely eradicated, and on-site audits in North America, where the risk of infection began to subside. The results showed that none of the companies had any major problems that could lead to environmental risks, and they were all actively engaged in activities to reduce their environmental footprint. Remote auditing does not enable us to see what is happening at the site. We used the check sheet in our fact finding about the sites, as is done in a typical audit. In addition, we gathered many different documents about the results of water tests and the administrative procedures of local affiliates before beginning the audit. We also conducted a paper audit. We plan to mainly conduct on-site audits, but will continue to carry out follow-ups checks using a web conference system as needed at areas where audits have already been completed, and plan to conduct further environmental audits of our group companies in other regions.

| Year | Area | Year | Area |

|---|---|---|---|

| 2007 | China | 2015 | Thailand |

| 2008 | — | 2016 | India and Indonesia |

| 2009 | Thailand and Indonesia | 2017 | Russia and China |

| 2010 | India | 2018 | Indonesia and Brazil |

| 2011 | Brazil | 2019 | China and the United States |

| 2012 | Russia and Czech Republic | 2020 | Europe |

| 2013 | United State | 2021 | China and Europe |

| 2014 | United States and Brazil | 2022 | Southeast Asia and the United States |

At overseas business units, employees in charge of the environment and safety in each region have gathered to hold regional meetings since FY2019. By exchanging information of and discussing common issues in the region, they aim to improve compliance and the level of the environmental impact reduction activities at each business unit. Meetings in FY2022 were held in North America, Latin America, Europe, Southeast Asia, South Africa and China, with the exception of Oceania. In these regions, meetings were held online due to COVID-19. These meetings were all attended by many participants who reported on their companies’ environmental activities. Through activities like this, we would like to further revitalize the environmental activities of the Komatsu Group.