Komatsu defines its strategic vision as a “solution partner that creates safe, highly productive, and clean workplaces.” Recognizing that improving safety at customer worksites where our products operate is a significant social issue, we have positioned the planning, development, and implementation of safety equipment and solutions as one of our key KPIs for addressing such challenges, and we continue to actively promote their advancement.

In 2013, Komatsu introduced ICT bulldozers with automated work equipment control, followed by ICT hydraulic excavators in 2014. These not only enhance productivity in civil engineering worksites through Smart Construction, but also contribute to worksite safety by eliminating the need for manual staking and surveying.

In the mining equipment sector, Komatsu was the first to bring the Autonomous Haulage System (AHS) to market. By combining advanced technologies such as communications satellites, radar, and sensors, we continue to meet customers' needs for safe, productive, and clean sites free of human intervention.

Komatsu has developed "KomVision," a system that uses onboard cameras and vehicle control technology to detect and alert operators when a person approaches a machine in operation. Since 2019, the system has been standard equipment on hydraulic excavators, and obstacle detection systems have since been introduced to dump trucks, wheel loaders, and motor graders.

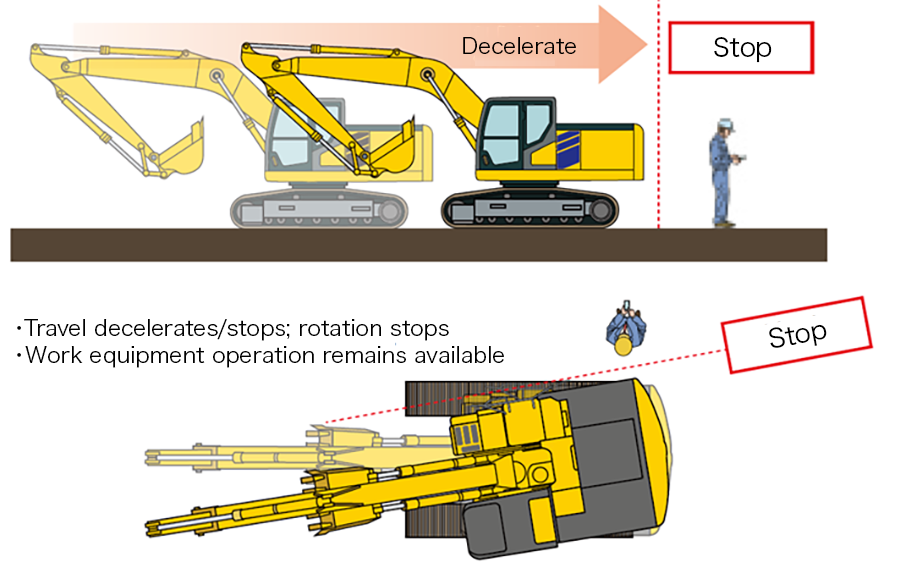

The hydraulic excavator PC200i-12, launched in December 2024, features an upgraded KomVision with a new "human + object detection mode" that detects not only people but also objects such as forklifts and vehicles. The addition of a quasi-millimeter wave radar has significantly improved detection accuracy.

When a person or object is detected near the machine during travel or turning, the system alerts the operator via the in-cab monitor and controls machine operations, stopping the machine during low-speed travel to help prevent collisions at the work site.

The system, offered as an option on the new WA380-8 and WA475-11 wheel loaders, detects nearby people, cargo, or vehicles while reversing, warns the operator, and automatically engages the brakes to decelerate or stop the machine when a collision risk is identified. It is designed to suit the unique structure and use conditions of wheel loaders, predicting movement direction based on steering angle. It also disables ground detection alerts automatically when performing tasks such as shoveling on uphill slopes to prevent false alarms from terrain near the machine's rear.

This system is not designed to prevent collisions under all conditions and has performance limitations.

- Traveling with suspended loads

- Working on steep slopes

- Operating on slippery surfaces or soft ground

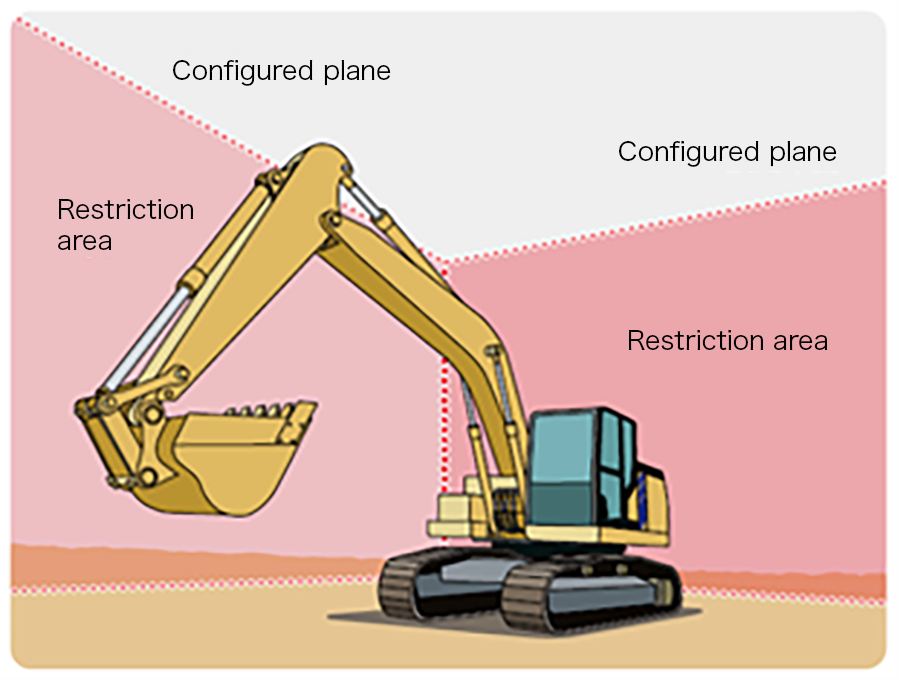

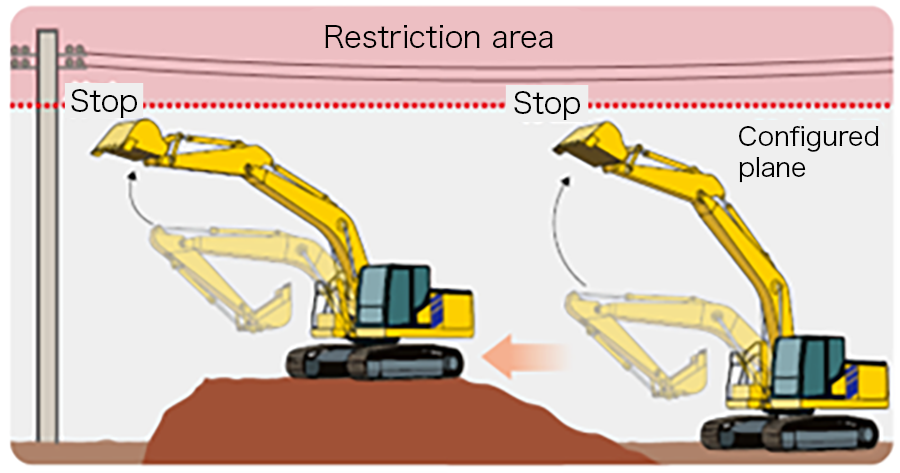

The PC200i-12 hydraulic excavator is also equipped with a new geofencing system that sets a virtual work restriction area around the machine. If the body or equipment approaches the restricted zone during operation, the machine automatically stops. Since the system incorporates elevation data, there is no need to reset the restriction area even when moving onto embankments. This helps avoid damage to overhead power lines, walls of nearby homes, and underground pipes, while also eliminating the need for monitoring personnel, thereby improving worksite safety.

Construction and mining equipment often operate on slopes, uneven terrain, or soft ground, where changes in load center during work can increase rollover risk — making it a key safety issue.

Komatsu’s CD110R-3, launched in 2023, became the industry's first full-rotation crawler carrier equipped with safety functions to reduce rollover risk. It uses an inertial measurement unit (IMU) to monitor tilt angle and alerts the operator when steep slopes are detected. In addition to the rollover warning, the machine is equipped with various safety-enhancing functions, including overload alerts, a raised dump body warning, and enhanced visibility through monitor displays.

The new PC200i-12 hydraulic excavator includes a rollover warning system that calculates the machine's center of gravity and monitors the working equipment's status to assess rollover risk and issue warnings.

The WA380-8 wheel loader comes standard with a warning system that alerts operators with a buzzer and indicator light when working on a slope at low speed and a rollover risk is present.

As a safety support function for dump trucks that operate for long hours at mining and quarry sites, this system uses a dashboard-mounted camera to monitor the operator’s face and posture. If drowsiness, distraction, or improper driving posture is detected, it alerts the operator with a warning voice and buzzer. The system also emits periodic voice prompts to check the operator's condition and, if no acknowledgment (such as hand movement in front of the camera) is detected, it prompts the operator to take a break.

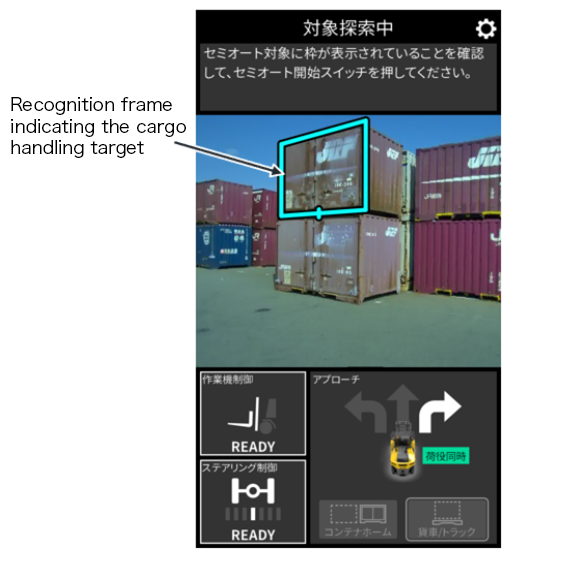

Since April 2023, Komatsu has been working with Japan Freight Railway Company to reduce operator workload and improve efficiency in handling large containers widely used in freight rail transport. In December 2024, we began deploying 21 forklifts equipped with guidance and semi-auto functions at 15 freight terminals nationwide.

The guidance system uses multiple onboard cameras to display the fork's height and center position—difficult for the operator to see directly—on an in-cab monitor. The system also supports the operator with an indicator that shows the inclination of the fork's top surface and a warning function that alerts the operator if the container is not securely engaged.

The semi-auto function utilizes LiDAR sensors and proprietary object recognition technology to align the forklift with a container and automatically insert the forks to within about 20 cm, using only the accelerator.

These features are expected to greatly reduce operator workload, prevent accidents such as container collisions or drops, and help address the growing shortage of skilled forklift operators.