Komatsu supports Midori-Kai member companies in a variety of ways. Main support activities that we have carried out are described below.

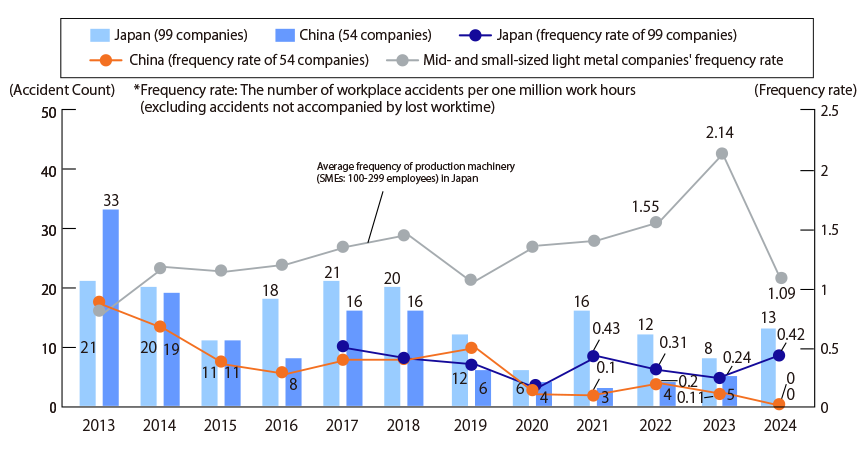

Komatsu provides support for the establishment of systems for safety activities and improvement of the activity level to 99 companies, the majority of which are custom goods suppliers out of the Midori-kai in Japan. The support includes continuous safety patrols by specialists from Komatsu, sharing information and horizontal application of occupational safety measures conducted by other companies, the introduction of management system, and so on. These activities are also carried out at the Midori-kai in China.

In addition, due to our business partners' labor shortages, there has been an increase in the number of foreigners, older adults, and women working onsite. Some of the workers from these groups have sustained injuries. In response, we have continued to provide support by making safety and health-related documents, such as work standards, available in multiple languages and creating a workplace environment that is less physically demanding for the elderly and female employees.

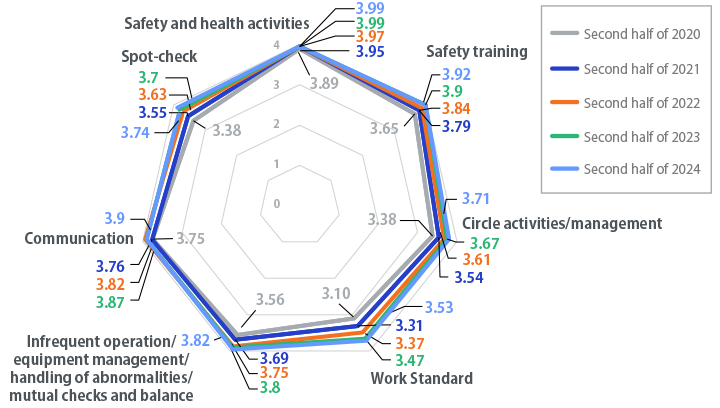

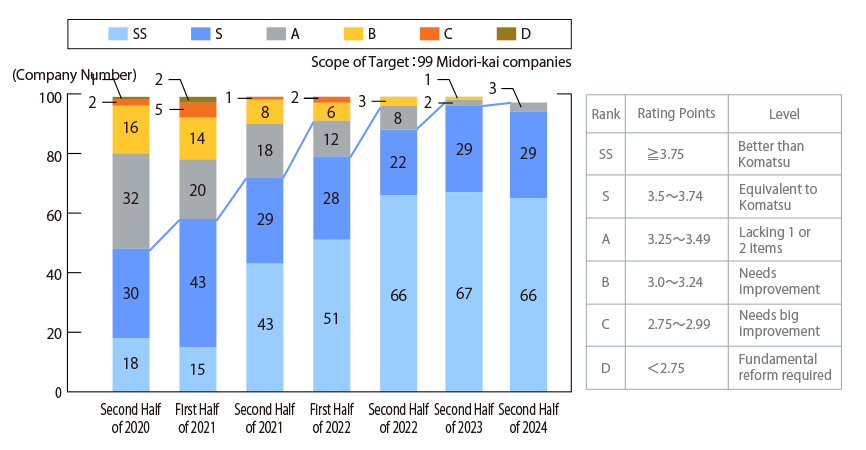

Using check sheets and on-site patrols, we conduct surveys to ensure compliance, particularly with laws (e.g., reports and inspections), unsafe locations on-site, and the existence of unsafe actions. If any issues are identified, we request the submission of a countermeasure report that details measures to prevent recurrence, followed up accordingly. From FY2018, we reviewed the check sheets and evaluation criteria to evaluate the activities of Midori-kai member companies using the same standards company-wide and follow-up (One-rank-up Activities) to improve the activity levels of each company annually. From FY2023, we created more site-focused check sheets to conduct safety activity checks at each company's site from the same perspective, strengthening our bottom-up activities.

In the follow-up, we also train on-site supervisors of business partners through fixed-point observation of work cycles on site and joint implementation of risk assessments.

To eliminate serious accidents, we regularly conduct comprehensive inspections of the safety devices installed on automated lines and machines and the operation of these devices, forklift and crane operations, and the status of the standards established for working in high places, using a unified check sheet. In particular, we are promoting safety measures for automated lines and machines, due to the policy to secure safety, not only by operators’ caution but by machines’ function and/or mechanism.

One of the Midori-kai committee activities is the implementation of mutual safety patrols by business partners with similar business standpoints. We also put a lot of weight on inspecting from perspectives specific to each business category (e.g. the handling of heavy goods or the risks of touching hot surfaces).

Executives from the Midori-kai member companies in Japan participate in the Komatsu Group Safety and Health Conference, which is held in June every year. Excellent Zero Accident circles selected from Japanese and Chinese Midori-kai member companies provide presentations about their activities. In addition, we open the Safety Dojo (Safety Training Hall), a facility included in each Komatsu plant, to our business partners, aiming to improve the safety awareness of the employees of each company through danger simulation experiences and danger prediction training.

We select companies that have had repeated accidents as target companies for Special Safety Activities, proposing specific improvements according to each company’s situation. We share the activity promotion plans created by each company and provide special support and guidance.

To elevate the level of activities at each company, we support them in acquiring occupational safety and health management systems, including ISO and OSHMS certification. In 2015, 97 companies adopted the Japan Industrial Safety and Health Association (JISHA)'s Workplace Safety Health Impact Project for small and medium-sized enterprises to objectively evaluate their compliance with safety and health laws through independent certified auditing bodies. For identified issues, we help develop corrective action plans, and Komatsu offers improvement guidance and support, leveraging our experts in response to requests from partner companies.

Changes in the results of safety activity evaluations from 2020 to 2024 (99 Midori-kai member companies, 116 offices)

Changes in the number of accidents at Midori-kai member companies in Japan and China

Status of one-rank-up activities

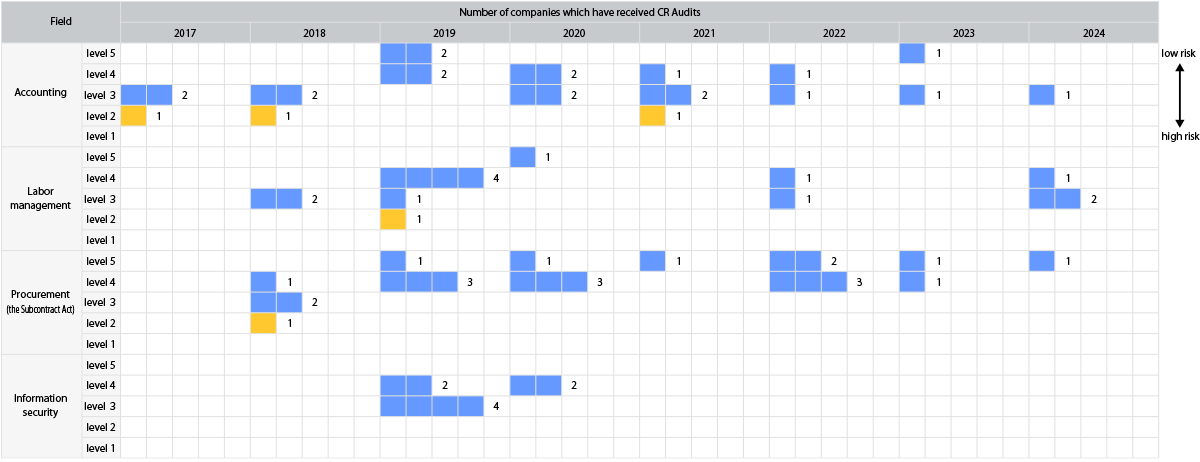

The Komatsu Group conducts compliance and risk audits (CR audits) and has extended these audits to 16 business partners in which Komatsu holds minority stakes since 2016. The audits cover four fields: accounting, labor management, procurement (Subcontract Act), and information security. They aim to identify potential risks and implement corrective measures. Compliance with relevant laws and regulations, the setting and operation of business rules, segregation of duties, decision-making authorities, and the inspection of related documents and on-site examinations are all part of the process to identify and address potential risks.

Voluntary establishment of compliance systems by business partners is essential for promoting CSR procurement. We believe that such a system should desirably be established by 1) formulating rules (establishing codes of conduct of each company), 2) building a structure for promoting CSR procurement (including the appointment of persons in charge of CSR procurement and practical affairs), 3) introducing a whistleblowing system, and then 4) providing employees with awareness training. Under this policy, we provided support to 99 companies, mainly custom goods suppliers belonging to the Midori-kai, for their establishment of compliance systems by providing practical examples at Komatsu and employee training materials, etc. As of the end of FY2021, we have completed support activities for all of the companies. The follow-up after completion of the support activities and the inspection of the status of the activities of major business partners will involve a SAQ survey.

In FY2023, no serious violations of Japanese labor-related laws and regulations or environmental violations were reported by any of Japan Midori-kai's 156 companies.

The problems found by CR audit and countermeasures (2017-2024)

| Items | Problem found by audit | Countermeasures |

|---|---|---|

| Finance & accounting | Workflow, operational guidelines, and decision-making authority are either not set or insufficiently defined | Establish and review workflow and guidelines, provide guidance for physical inventory implementation, etc. |

| Physical inventory (including fixed assets) is either not conducted or not performed regularly and timely | ||

| The rules for the disposal and forced evaluation loss of idle assets are unclear | Separate approvers and applicants, etc. | |

| Management of company official seals, password updates for the accounting system, and access control are inadequate | ||

| Labor management | Deficiencies in subcontractor agreements with self-employed person | Switch to direct employment, review time card operations, etc. |

| Handling of fractions (less than 30 minutes) in working hours management | ||

| Procurement (Subcontract Act) | Lack of necessary information in order forms (Article 3 documents): provisional price, payment terms, etc. | Review order forms and supplementary documents, review workflows, etc. |

| Risk of delayed payments (within 60 days of receipt) | ||

| Risk of early offsetting of the cost of supplied materials | ||

| Violation of the prohibition on subcontract payment reductions (reduction of the equivalent amount of discount fees due to cash payments) | ||

| Unclear rules for obtaining evidence of counterparty consent when canceling orders |

Result of CR audit to level-1 critical suppliers

Komatsu believes that the greatest support we can provide to Midori-kai member companies is human resource development, and thus, we offer various programs tailored to different levels within the organization (see table below). From FY2020 to FY2022, we had to cancel most face-to-face training programs due to the COVID-19 pandemic. As an alternative, we provided remote education curricula using online meeting systems, which could also be utilized as employee training materials by Midori-kai companies. Since 2023, we have resumed in-person training and have been implementing a hybrid approach that combines both remote and face-to-face learning.

In recent years, we have particularly focused on "Management Salons" and "Skills Transfer Activities." The Management Salons aim to develop young managers who have recently taken on new business responsibilities. During these sessions, Komatsu executives and company managers analyze the current strengths and weaknesses of each company and exchange views on their medium-term management visions, aligning and sharing policies and ideas. Skills Transfer Activities are designed to facilitate the improvement and succession of on-site skills. Through these activities, we assist companies in building systems for promoting skills transfer and skills evaluation, and in developing instructors in key skill areas by sharing Komatsu's expertise.

Training and Other Programs for Midori-kai Member Companies

| Target job level | Program | Outline | Major achievements | FY2024 results |

|---|---|---|---|---|

| Management | Commissioned training | Komatsu accepts sons and daughters of corporate managers of member companies and provides them with on-the-job training for up to five years. | 58 trainees have been accepted since 1972. | 2 person |

| Middle management training | Komatsu's training program for its executive candidates is open to candidates for member company successor. Duration of the training is seven months. | 31 people have participated since 2005. | 1 person | |

| Management Salons | Young corporate managers of member companies make presentations on medium-term management visions of their respective companies, which are discussed and shared with Komatsu. | Provided to a total of 37 companies since 2014 | 5 companies | |

| Employees in managerial positions | Managerial training | For newly appointed managers and on-site job leaders (e.g. general managers of centers and team leaders) | Around 40 people participate every year. | 53 people |

| Leader training (for field managers) | Exclusive training programs for the Midori-kai. The training is provided two times a year. | Around 60 people participate every year. | 70 people | |

| Representatives | Komatsu Technical Institute | Intended for leader candidates related to production engineering and manufacturing who are aged 30 or younger. It is a boarding school which provides a two-year program. | 33 people have entered since 2008. | Zero |

| Production engineer training | It is an exclusive training program for the Midori-kai on sheet metal processing and mechanical engineering. Five-day training is provided once a year. | Around 40 people participate every year. | 19 people | |

| Skilled workers | Instructor training | A 30-day program for candidates for skilled instructors of each company | 170 people have participated since 2015. | 21 people |

| Inspection training school | Inspection skills training and classroom lectures | Held as needed | 79 people | |

| Others | All Komatsu QC competition | Participants are selected from among the Midori-kai members. | Around 20 companies participate every year. | 5 companies |

| All Komatsu skills competition (Advanced Technique Contest) | Participants are selected from among the Midori-kai members. | 29 people 18 companies |

||

| All Komatsu Safety Competition | Participants are selected from among the Midori-kai members (report on Excellent Zero Accident circles’ activities). | Around 5 companies participate every year. | 4 companies |

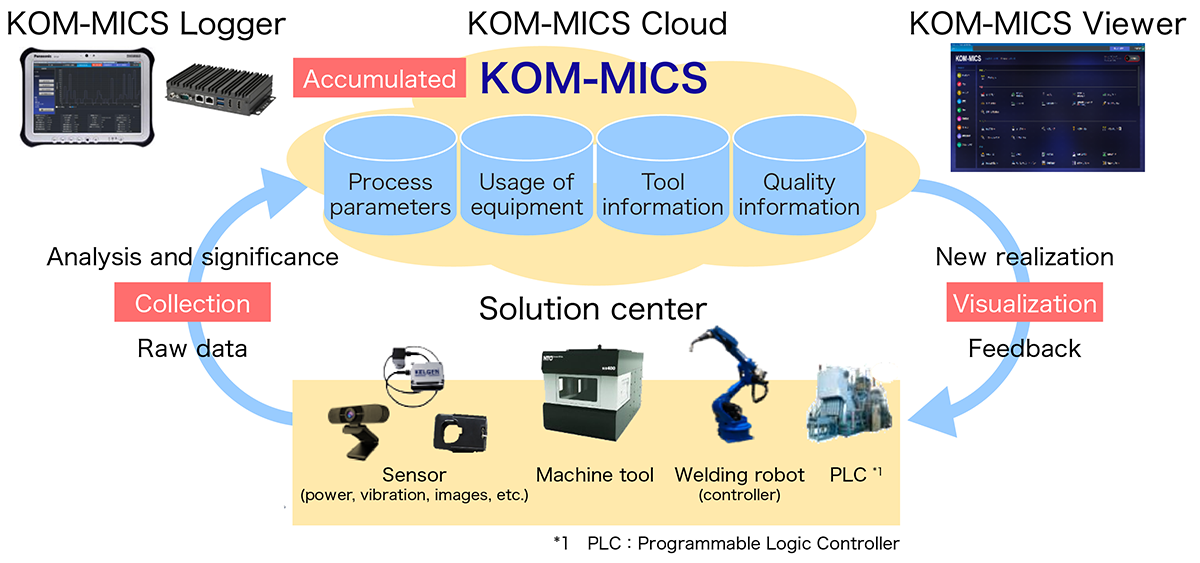

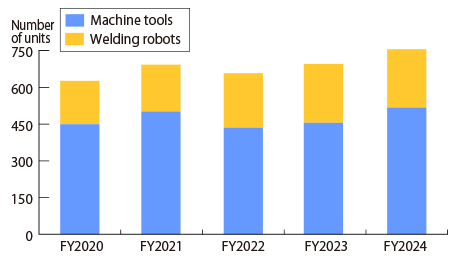

Addressing the issue of the labor shortage, which has been growing more serious in recent years, is an urgent task for Komatsu and members of the Midori-kai. Komatsu continues to promote the networking of production sites and facilities using ICT (KOM-MICS) and improving productivity and labor efficiency through its application. As a countermeasure against the labor shortage, we are expanding these activities to members of the Midori-kai. Through tools such as the KOM-MICS Logger, developed by Komatsu, data on operational status and operating conditions from machine tools and welding robots are automatically collected from each company's controllers and accumulated on the network. These data are then processed and edited on a PC using applications designed for specific purposes, visualizing issues related to improving operating rates and leading to collaborative analysis and implementation of improvement measures.

Outline of KOM-MICS

Change in the number of KOM-MICS Loggers installed

In addition to the frequent occurrence of natural disasters such as earthquakes, heavy rains, and typhoons in recent years, new threats such as the COVID-19 pandemic and cyberattacks have also become apparent. The importance of establishing a BCP system for the supply chain is increasingly critical. Starting after the Great East Japan Earthquake in 2011, Komatsu has provided support by implementing measures to withstand earthquakes and water damage, etc. at the buildings and facilities of 104 companies, mainly custom goods suppliers belonging to the Midori-kai. In addition to these tangible measures, it is also necessary to strengthen intangible measures, including the establishment of an initial response system by creating a BCP manual, etc., and a system for facilitating early restoration of business operations. Since FY 2019, we have held BCP workshops for 104 Midori-kai member companies, mainly focusing on support for the establishment of their own initial response systems.

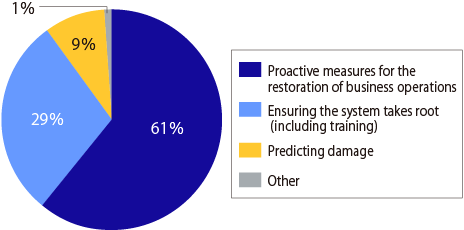

In the future, we will extend our support to activities to enable the system take root through simulations and other activities, something that many of our business partners believe necessary for the promotion of BCP, and to proactively prepare to restore business operations (e.g. the sharing of information, dispersion of in-house production capacity, consideration of collaboration with other companies in the same industry).

Issues to consider when advancing the company’s BCP (responses obtained from 87 Midori-kai companies)