We have requested all member companies of the Midori-kai in Japan and China to obtain certifications for environmental management systems (EMS), such as ISO14001 and Eco-Stage, and provided them with instructions and support for obtaining the certifications. In Japan, all 156 member companies have obtained the certifications, and we began to check the renewal status of the certifications in 2018. In China, a total of 60 companies have already obtained the certifications. We encourage Midori-kai companies in the U.S., Europe, and Thailand to obtain similar certifications.

Over ten years have already passed since the Midori-kai members in Japan obtained the certifications. Like in the case of the safety and health activities, it is important to follow-up the status of the certifications in each company's business activities. To realize this, we started environmental audits for the outsourcing companies of the Midori-kai from 2021, and 4 companies were audited by 2023. Through written surveys on compliance with environment-related laws and regulations, etc., and on-site inspections at each company's offices, we evaluate how well EMS has been established on site and promote activities to support further improvements. Since FY2022, we have expanded check sheet-based voluntary verification to all Midori-kai outsourcing companies in Japan and have held study sessions on environmental laws and regulations. In FY2023, we conducted specialized training focused on the Water Pollution Control Act and the Sewerage Act, which were identified as having the most relevant facilities through our written surveys. We will continue to increase the number of onsite audits, especially for companies bearing anticipated risks.

Environmental audits

Number of Midori-kai member companies with EMS certifications (as of the end of April 2025)

| Region | Number of member companies | Number of companies which have obtained certification | Percentage of companies with certification | ||||||

|---|---|---|---|---|---|---|---|---|---|

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | FY2025 Target |

FY2025 Target |

FY2024 Progress |

||

| Japan | 156 | 156 | 156 | 156 | 156 | 155 | 156 | 100% | 100% |

| China | 63 | 58 | 60 | 60 | 60 | 60 | 63 | 100% | 95% |

| Thailand | 32 | 16 | 16 | 18 | 20 | 20 | 30 | 95% | 63% |

| North America | 44 | 19 | 27 | 27 | 27 | 27 | 42 | 95% | 61% |

| Europe | 40 | 34 | 34 | 35 | 35 | 35 | 38 | 95% | 88% |

| Total | 335 | 283 | 293 | 296 | 298 | 297 | 329 | 98% | 89% |

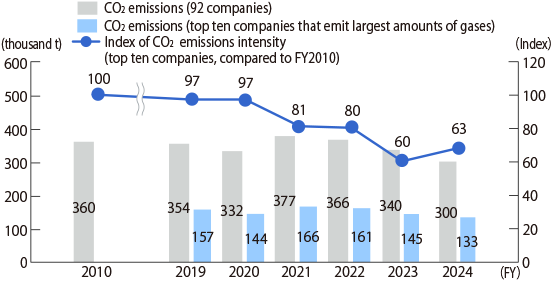

Komatsu has set a mid-term ESG target of 50% reduction in CO2 emissions in products and production (compared to 2010) by FY2030 and promotes improvement activities. In recent years, we have emphasized the importance of reducing CO2 emissions in the entire supply chain related to its own business, and worked to reduce CO2 emissions from manufacturing process of purchased parts and materials, which account for about 10% of indirect CO2 emissions (Scope 3) other than Scope 1 and 2.

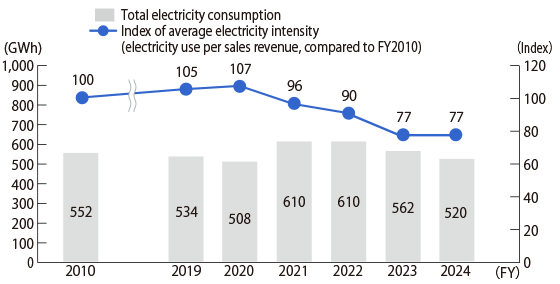

From 2012 to 2016, in response to tight power supply and demand and the steep increase in electricity costs following the Great East Japan Earthquake, we began to roll out activities to reduce the power consumption of 96 Midori-kai companies in Japan by setting a target reduction in electricity consumption of at least 15% compared to 2010. Despite comparative obstacles due to large fluctuations in production volumes and new capital investments, we almost achieved our target by the end of FY2016. As a result of the expansion of these activities across all our suppliers, some suppliers won the ECCJ Energy Conservation Grand Prize Award. Since 2017, we have worked to maintain and improve the level of reduction through independent improvements at each company. Since FY2019, we have also been providing concrete support for the reduction of CO2 emissions in all kinds of energy use, including electricity, heavy oil, and gas, targeting the top ten highest-emitting casting, forging, and heat treatment companies. From FY2023, we have requested that all of 156 Midori-kai companies set mid- and long-term reduction targets in accordance with the SBT and implement tangible improvement activities. In particular, in parallel with this effort, CO2 reduction activities have been initiated with 92 external partner companies affiliated with the Midori-kai group, setting a common target of reducing CO2 emissions by 20% on an intensity basis by FY2030 compared to FY2022. With the start of activities in FY2022, we introduced our latest case studies of improvements. We are promoting CO2 reduction through technical exchange meetings and other activities in collaboration with our improvement promotion division and the Midori-kai committee. Starting FY2023, especially for forging and casting manufacturers with high CO2 emissions, we actively promoted improvement activities by sharing improvement content through on-site visits and holding case sharing meetings among companies. The progress of each activity is monitored through periodic CO2 emissions surveys and SAQ questionnaires.

Changes in electricity consumption

(Midori-kai 92 companies)

Independent practitioner's assurance

Change in CO2 emissions

(Midori-kai 92 companies)

Independent practitioner's assurance

Status of setting of targets for the reduction of GHG emissions (155 companies in the Midori-kai)

| Already set | Not set/not answered yet | |

|---|---|---|

| Short-term target | 142 | 13 |

| Medium- and long-term target | 61 | 74 |

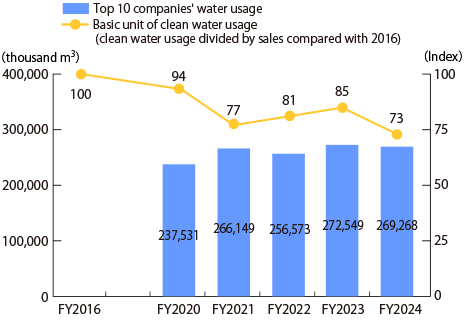

We are inspecting 135 offices of 96 Midori-kai members in Japan to understand their general water risks, including the above-mentioned flood and tsunami risks, location environments, potential and actual water intake/discharge capacities, water quality, and how they address these issues. We also use Aqueduct in these analyses.

In response to these investigations, we have been conducting activities to reduce water consumption since FY2017. In these activities, the top ten companies in the consumption of clean water are considered to be model companies and we present Komatsu improvement examples and provide guidance on improvement through on-site visits, with a target of 15% reduction of water consumption by FY2021. In FY2018, the target was achieved. Since then, we have voluntarily stayed aware of the amount of water used and have extended the activities to other Midori-kai companies through the distribution of improvement examples from Komatsu and ten other companies. We have also conducted environmental audits and confirmed compliance with the Water Pollution Control Act and other water-related laws and regulations since FY2020.

Changes in clean water usage by Midori-kai's top 10 companies

The basic goal of the environmental regulations in China is the elimination of three things: exhaust gases, discharged water, and solid waste. However, when operating under those regulations, the regulations and standards set forth by each local government have priority. Regarding discharged water from plants, to address the aggravated water pollution in rivers and lakes, the standards for BOD/COD (Biochemical Oxygen Demand/Chemical Oxygen Demand), which are indexes of amounts of organic substances in discharged water, are strict when compared to the country-wide standards in Japan, and there is an increasing number of cases where centralized water treatment systems for discharged water, etc. need to be installed.

Komatsu checks the regulatory compliance status of the Midori-kai members in China on a regular basis.

In addition, in China, extremely tough environmental regulations were imposed in 2015, mainly in the coastal areas, aiming to improve air pollution issues (PM2.5) drastically. As a result, companies engaging in businesses such as painting, welding, casting and plating are required to take thorough measures to reduce exhaust air, smoke and soot (including VOCs). Working together with member companies of the Midori-kai in China, we provide support for complying with the regulations, including the installation of facilities. As a result of measures taken by the companies, 18 companies had been certified as exempt from the regulations (as green companies) as of March 31, 2022. We will continue to work with each company to reduce risks to our business continuity.

In 2011, Komatsu announced the “Declaration of Biodiversity by Komatsu,” which outlines our commitment to reducing environmental impact through business activities and promoting conservation through social contribution efforts. Midori-kai member companies support this policy and collaborate with us to engage in environmental conservation and other community contribution activities across various regions. Since FY2021, Komatsu has been encouraging member companies to develop their own initiatives tailored to local conditions by providing education programs. In addition, we collect annual reports from each company on their activities and share these examples among all members to promote mutual learning and the dissemination of best practices.