Komatsu's commitment to quality and reliability is encapsulated within the fundamental principle of “Monozukuri” (manufacturing competitiveness). With this in mind, we are dedicated to maintaining a portfolio of first-class products-both hardware and software−that builds on customer satisfaction. Our basic managerial policies have a strong focus on customer-centricity, creating a manufacturing ecosystem that places customer satisfaction at the forefront of its priorities. We maintain the standards of quality that have become an integral part of our organizational culture through a continuous process of assessment and refinement that takes place across all areas of our production process.

Our quality management systems touch on a number of specific fields, such as the global environment, quality assurance, and the education and training of our personnel. We also evaluate our performance in these areas using a number of key performance indicators.

Komatsu's basic approach to quality assurance is to "ensure customer satisfaction by providing products that meet customer needs and effectively conducting support activities to ensure these products fully function, in cooperation with affiliates, cooperating companies, distributors, dealers, and all other Komatsu entities across all activities from planning, development, production, sales, to after-sales service."

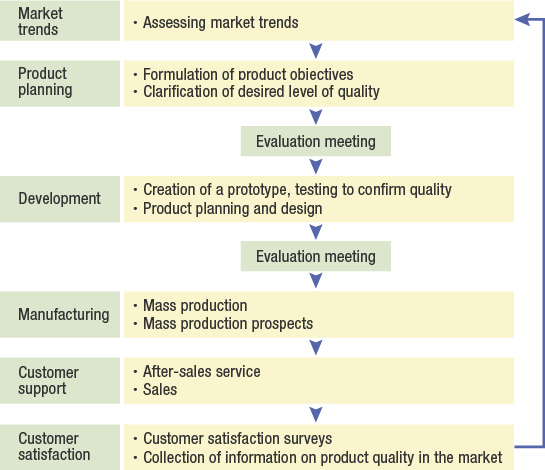

Komatsu employees across all areas of our operations, from product planning to development, manufacturing, sales, and after-sales service, work together as a single cohesive unit to ensure that the products we develop are safe, innovative, and of high quality. Our unique “monozukuri” system enables the creation and subsequent introduction of highly competitive DANTOTSU products into the market, whilst maintaining our significant competitive advantage through goods and services with a wide array of substantial features.

At each step of the development and manufacturing process, various meetings and evaluations are conducted to assess conformity and promote activities aimed at achieving goals, ensuring quality and reliability through rigorous quality assurance activities.

Through these efforts, Komatsu provides products and services that consider the global environment, comply with international standards and regulations of various countries, and strive to improve customer safety and satisfaction.

The majority of Komatsu's products, such as construction and mining equipment, utility equipment (compact machines), forest machines, and industrial machinery, are used as manufacturing equipment at customer work sites. These products are required to contribute to customers' operations with high utilization rates and productivity over long hours every day. Reflecting these product characteristics, Komatsu's sales and service staff visit customers directly to provide detailed advice and maintenance activities related to products and work methods. They also collect customer feedback and requests about the products and quickly relay this information to the relevant departments to enhance customer satisfaction.

Komatsu also maintains comprehensive databases on market information regarding product quality. Company staff are able to utilize this wealth of information to ensure the rapid resolution of quality-related issues, should they be raised.

Komatsu uses ICT-based remote vehicle management systems in order to track the current status of a vehicle's health, its operating status, and other relevant information metrics. Komatsu has equipped general construction equipment with Komtrax and large mining equipment with Komtrax Plus. By utilizing this information in products and services, Komatsu contributes to improving the operating rates of customers' vehicles and reducing maintenance costs, thus providing comprehensive lifecycle support.

The goal of Komatsu's global quality assurance activities is to achieve a unified quality level at all locations worldwide. To this end, we engage in activities aimed at standardized technical drawings, manufacturing systems, inspection methods, information collection, and quality management across all regions.

Komatsu has a number of manufacturing facilities that it refers to as “Mother plants”. These plants have product development capabilities and serve as the central hub for global product development initiatives using cutting-edge technologies and techniques. Any form of progress or advancement that is conceived at a “Mother plant” is immediately disseminated to other Komatsu manufacturing locations around the world, creating a uniform ecosystem that promotes technological development and enhances product quality.

Komatsu prioritizes safety and reliability of our products as the most important issues in its quality assurance activities. By establishing product safety action standards and guidelines, and ensuring that all employees comply with them as a united team, we aim to provide products that are safe, reliable for long-term use.

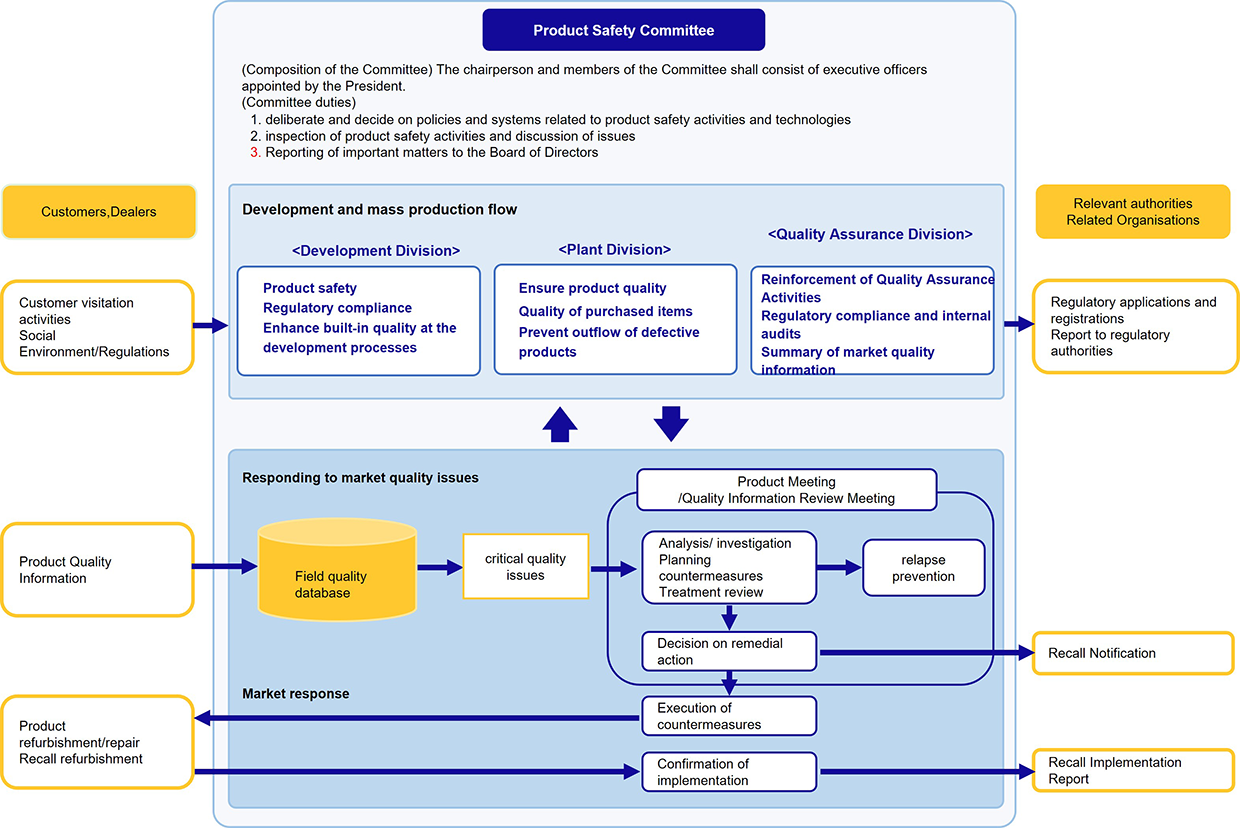

To quickly detect product safety issues in the market, Komatsu has established an information system for product safety to ensure rapid responses. Centered around the company-wide product safety committee, we have built a system that allows for the rapid execution of a series of activities, including (1) analysis and handling of accident causes, (2) communication with relevant government authorities, and (3) making decisions on corrective measures such as product recalls, involving top management to continually make improvements.

The methods for providing product safety information to customers are as follows:

Komatsu strictly oversees compliance with legal requirements. Should a defect be found in its products, the company initiates prompt correction measures and moves forward with proactive information disclosure, and strive to ensure safety in the market.

Komatsu strictly oversees compliance with legal requirements. Should a defect be found in its products or services, the company initiates prompt correction measures and moves forward with proactive information disclosure.

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Number of recalls issued (cases) | 13 | 7 | 6 |

| Number of units (units) | 6,483 | 5,062 | 2,532 |