The management principle of Komatsu is to maximize its corporate value through the commitment to “Quality and Reliability.” Any uncertainty that hinders this pursuit is considered a “risk,” and measures are taken to address all risks threatening the sustainable development of the Komatsu Group.

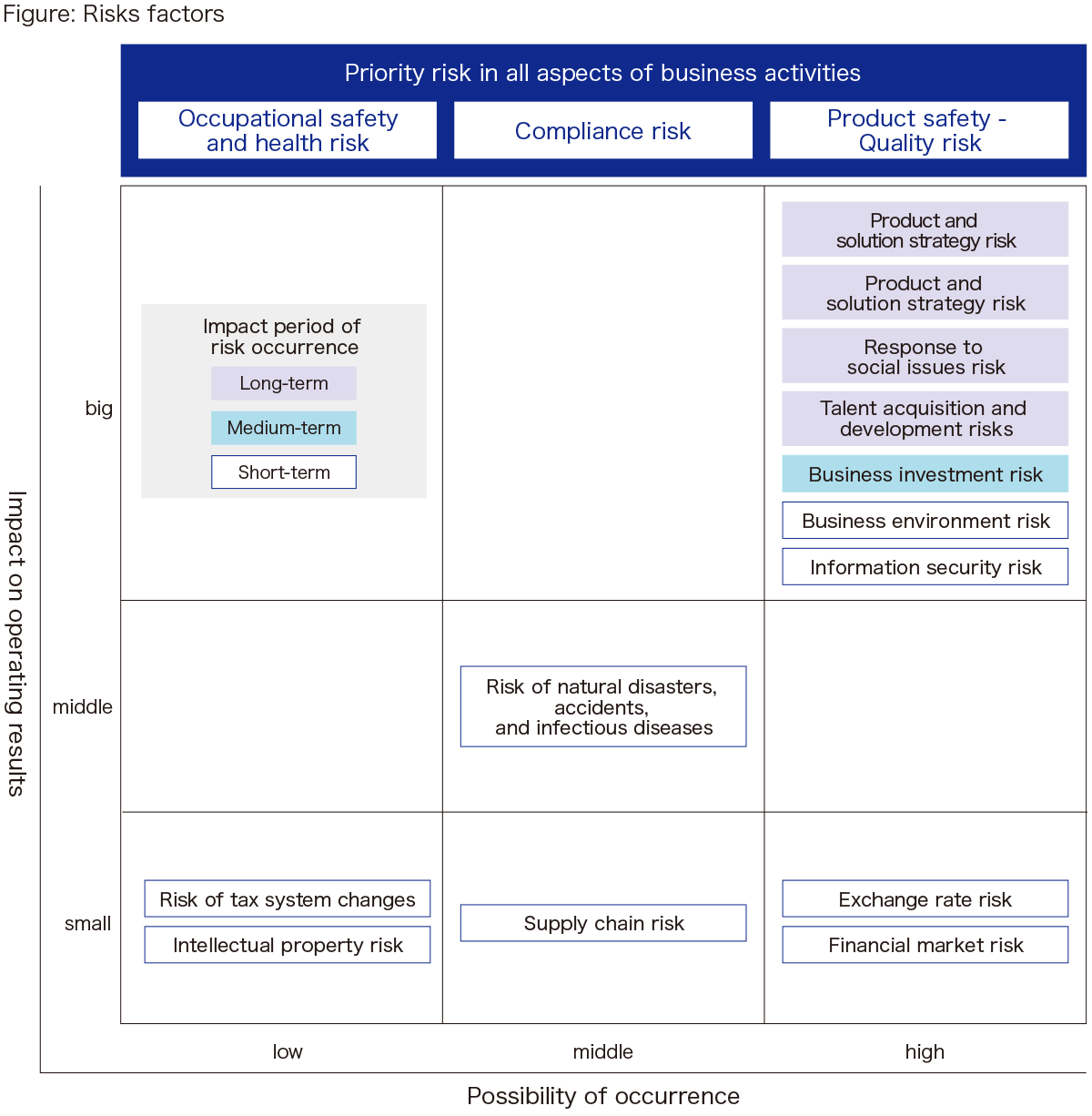

Komatsu identifies risks that may affect its business activities from an enterprise-wide perspective and evaluates them based on “impact on business performance,” “likelihood of occurrence,” and “impact duration in case of risk occurrence,” to determine the priority of risks. Furthermore, the company identifies “corporate risks,” which are significant enterprise-wide risks, and “regional risks,” which are specific to the business activities of each country and region. After determining the responsible departments for countermeasures, activities are carried out to avoid or minimize risks and maximize opportunities. In FY2024, risks and opportunities were identified and evaluated based on changes in the business environment, reflecting the materiality analysis conducted during the formulation of the new mid-term management plan (2025–2027).

To further strengthen its risk management, Komatsu has established a Risk Management Committee, chaired by the President, with the Executive Officer Supervising General Affairs as Vice Chairman and the Risk Management Group of the General Affairs Department acting as the Secretariat. This committee is responsible for developing a comprehensive corporate policy on risk management, identifying “corporate risks” through the selection and evaluation of risks from an enterprise-wide perspective, inspecting and following up on the implementation status of risk countermeasures, and controlling risks when they materialize. In FY2024, the committee was convened in June, October, and February, and the content of its deliberations and activities is regularly reported to the Board of Directors.

The risk map (risk prioritization) based on FY2024 risk assessment results is as follows. For details on the risks, please refer to the 156th Securities Report.

Risk assessment results (change from previous year)

| Category | Item | Impact on operating results | Possibility of occurrence | Impact period |

|---|---|---|---|---|

| Strategic risk | Product and solution strategy | Big | High | Long-term |

| Business environment | Big | High | Short-term | |

| Business investment | Medium → Big | Medium → High | Medium-term | |

| Response to social issues | Big | High | Long-term | |

| Operational risk | Supply chain | Medium → Small | Medium | Short-term |

| Talent acquisition and development | Big | High | Long-term | |

| Information security | Medium → Big | High | Short-term | |

| Intellectual property | Small | Low | Short-term | |

| Financial risk | Fluctuations in financial markets | Small | High | Short-term |

| Changes in tax systems | Small | Low | Short-term | |

| Foreign exchange fluctuations | Small | High | Short-term | |

| Hazard risk | War, terrorism, and geopolitical | Big | High | Long-term |

| Natural disasters, accidents, and infectious diseases | Medium | Medium | Short-term |

The corporate risks for FY2024 are as follows.

| Risks related to product and solution strategies | |

|---|---|

| Risk description | Komatsu defines its purpose as “creating value through manufacturing and technology innovation to empower a sustainable future where people, businesses, and our planet thrive together.” In line with anticipated future market and societal needs, we are promoting the creation and market introduction of new products and solutions, such as electrified machinery, Smart Construction, mine automation (e.g., AHS), and data-driven businesses (e.g., KOMTRAX). However, as the global movement toward low-carbon technologies and electrification accelerates, we face the risk of losing competitiveness in the market if we are unable to develop products and solutions that meet customer needs by the time they are required by the market, or if our developed offerings fail to gain customer acceptance. In particular, if electrification becomes mainstream in the market, our business model itself must evolve in response to such changes. Failure to adapt may not only result in the loss of existing revenue sources but also lead to a decline in our overall market competitiveness. |

| Impact on Business | If we are unable to provide products and solutions that maintain an advantage over competitors, it could affect our business performance, and this impact could be prolonged. |

| Risk mitigation actions | From 2020 to 2024, Komatsu introduced seven models of electrified construction equipment, primarily in the European and Japanese markets. Going forward, we aim to expand the product lineup to offer more options for customers. To address the challenge of charging infrastructure for electrified equipment, we have begun a proof-of-concept (PoC) project for a power supply unit for electric mini excavators, jointly developed with partner companies using hydrogen co-firing engine technology. At bauma 2025 held in Germany in April 2025, under the themes of innovation, sustainability, and digitalization, Komatsu exhibited the European model of our next-generation hydraulic excavator, the PC220LCi-12, for the first time. We also showcased five models of electric excavators, our new-generation wheel loaders WA485-11/WA475-11 with significantly improved fuel efficiency, as well as various charging and storage solutions tailored to diverse jobsite needs. To accelerate technological innovation, Komatsu acquired American Battery Solutions Inc. (ABS), a U.S.-based battery manufacturer, in 2023. This acquisition enables us to integrate ABS’s battery technology with Komatsu’s expertise, advancing the development and production of batteries for construction and mining equipment adapted to various environments. We are now working to expand the use of ABS batteries across more equipment models and promote in-house production of key components for electrified construction equipment. These efforts also contribute to the establishment of a value chain business that supports the entire lifecycle of electrified construction equipment. In addition, in 2024, as a new initiative to reduce environmental impact, Komatsu is collaborating with Vale, a major mining company in Brazil, and Cummins, a leading U.S.-based engine manufacturer, to develop engines for our ultra-large dump trucks capable of operating on a diesel-ethanol blended fuel. Through this collaboration, we aim to gradually convert Komatsu’s 830E and 930E trucks operating at Vale's mine sites to a lower-emission dual-fuel specification over the coming years, thereby contributing to CO2 reduction and enhancing sustainability in mining operations. Furthermore, Komatsu has developed a concept model of its flagship mining truck, the HD785, equipped with a hydrogen-only engine and has started demonstration testing at its Ibaraki Plant. This is the world’s first attempt to install a hydrogen engine in a large dump truck. Through this trial, we aim to accumulate knowledge on the use of hydrogen engines, which will support the development of future “hydrogen-powered construction equipment.” In this way, we are advancing the development and deployment of new power sources to achieve carbon neutrality. We are jointly developing the hydrogen engine with KEYOU GmbH, a German startup, and the demonstration project includes data collection on performance, continuous operation time, and fuel efficiency, along with safety verification. We also plan to address issues such as hydrogen infrastructure and safety management through collaboration with industry associations and relevant stakeholders. In addition, Komatsu operates a global remanufacturing (reman) business that collects and regenerates components such as engines and transmissions after long-term use at customer sites. This resource-circulating business is a key element of our component strategy. In November 2023, we began remanufacturing key components (capacitors and inverters) of hybrid hydraulic excavators in Japan. As a result, nearly all key components developed and produced in-house by Komatsu are now eligible for remanufacturing, contributing to both cost savings and environmental impact reduction. To grow our solution business, we established a new company, EARTHBRAIN Ltd., in April 2021, in collaboration with NTT Docomo, Sony Semiconductor Solutions Corporation, and Nomura Research Institute, Ltd. As workstyle reforms are required at construction sites worldwide, we are promoting DX (Digital Transformation) in the construction industry, aiming to improve safety, productivity, and environmental performance. For example, we jointly developed a remote control system for construction equipment with EARTHBRAIN and started providing it to customers in March 2023. This system, through its integration with Smart Construction Fleet and 3D Machine Guidance, helps to maximize work efficiency and enhance safety. In addition to expanding the sales of ICT construction equipment, we also expanded our business by promoting "Smart Construction 3D Machine Guidance," which allows for the retrofitting of ICT functions such as machine guidance, in overseas markets. In December 2024, we launched a fully redesigned 20-ton class hydraulic excavator—our mainstay model for civil engineering—as the "PC200i-12." This next-generation hydraulic excavator comes standard with 3D Machine Guidance that integrates with Smart Construction®, enabling improved safety and productivity. It is also designed to allow even less-experienced operators to work with less stress. Moreover, it contributes to workstyle reforms in the construction industry by enabling progress monitoring and analysis without having to visit the job site. With respect to promoting automation at mine sites, we have steadily advanced the introduction of the Autonomous Haulage System (AHS) for mining operations, reaching a cumulative total of 862 units in operation as of the end of March 2025. Furthermore, aiming to balance both safety and productivity, we began efforts in June 2020 to introduce remote-controlled bulldozers for mines and, in May 2023, started commercial operation of the large ICT bulldozer “D375Ai-8 Remote Control Specification.” |

| Risks associated with addressing social issues (a)Response to climate change |

|

|---|---|

| Risk description | Our company operates globally and recognizes various social issues, including climate change, water resource depletion, and human rights concerns. While we aim to address these issues sincerely and fulfill our social and environmental responsibilities as a global company, contributing to society through our business activities, there is a risk that our efforts may be deemed insufficient by society. This perception could negatively impact our business performance by damaging our brand image and social credibility. |

| Impact on business | We have long prioritized environmental initiatives as one of our top management priorities. In 2021, we declared our goal to achieve carbon neutrality by 2050, and in our medium-term management plan launched in April 2025, we set this declaration as a challenge goal and actively pursued related activities. However, if our responses to social issues are deemed inadequate by stakeholders, it could affect our business performance and potentially prolong these impacts. |

| Risk mitigation actions | To reduce the risks of climate change, Komatsu is working to significantly reduce emissions during product operation—which account for the majority of CO2 emissions over the entire lifecycle—by advancing the market introduction of electrified construction equipment and conducting pioneering research into fuel cells and hydrogen engines. In the mining sector, we are developing “power agnostic trucks” that can run on a variety of energy sources, in collaboration with 12 major resource companies as part of a GHG Alliance. We are also promoting activities to achieve a low-carbon society as an industry leader by enabling highly efficient operations through autonomous driving and remote operation powered by advanced digital technologies. Based on the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD), we evaluate climate-related risks and opportunities for Komatsu and conduct scenario analysis to enhance our resilience. At the same time, we actively promote our climate change and water security initiatives through constructive dialogue with stakeholders. Through these efforts, we aim to achieve ambitious targets: by 2030, we plan to reduce CO2 emissions by 50% compared to 2010 levels and raise the use of renewable energy to 50%. These goals are milestones toward our challenge target of achieving carbon neutrality by 2050—effectively net-zero CO2 emissions, where emissions are balanced with absorption. |

| (b) Reputational risk related to the forestry equipment business | |

| Risk description | Forests play a vital role in mitigating climate change by absorbing carbon dioxide from the atmosphere. One of the benefits derived from forests is timber, which can store the carbon absorbed during tree growth for extended periods unless burned. As timber and paper are renewable materials, they have recently attracted attention as alternatives to plastic. These advantages can be achieved at relatively low cost, thus requiring healthy forest cultivation and proper forest management. Meanwhile, forestry remains one of the most hazardous industries globally, and the introduction of forestry equipment is essential for improving both operational efficiency and worker safety. Mechanization contributes to the realization of safer and more sustainable forestry practices. In light of this external environment, Komatsu aims to contribute to a circular forestry model that promotes the sustainable use and regeneration of forest resources while pursuing harmony among the environment, the economy, and society. However, if the importance of sustainably using and regenerating forest resources is not effectively communicated, our initiatives and the essential role of forestry may be misunderstood. In particular, if logging equipments or logging scenes are disproportionately emphasized, it may lead to the misconception that Komatsu is contributing to deforestation or neglecting environmental considerations. Such misunderstandings may result in reputational risk, where our environmental efforts and social responsibilities are misinterpreted or undervalued. |

| Impact on business | Komatsu positions the forestry equipment business as its third pillar, following the construction and mining equipment businesses, and is actively working to strengthen it. This business is being expanded through mergers and acquisitions, offering equipment for logging, processing, forwarding, and planting, as well as fleet management and solutions for logging and timber transport. However, if the aforementioned risks materialize and our environmental considerations are perceived as insufficient, we may lose support from environmentally conscious customers and investors. This could damage our brand value, lead to reduced business transactions, and ultimately result in a decline in sales. Furthermore, as ESG and environmental regulations are tightened, increased compliance costs could reduce the profitability and competitiveness of the business, negatively impacting our overall growth strategy. |

| Risk mitigation actions | Komatsu believes it is essential to properly communicate the significance of forestry equipment in supporting sustainable forest management and promoting circular forestry. We actively share the positive aspects of forestry, such as our reforestation efforts following logging, the carbon fixation benefits of timber, enhanced safety through mechanization, and the efficient carbon absorption capabilities of forests. To demonstrate our commitment to environmental and social responsibility, we are also enhancing our information disclosure in line with ESG and SDGs frameworks. In addition to reducing CO₂ emissions from construction and mining equipment, Komatsu recognizes the environmental protection role of forests and the growing importance of circular economy initiatives. Since forest management and planting still rely heavily on manual labor, we are developing afforestation equipment such as the Planter and our Smart Forestry solutions. These innovations aim to improve operational efficiency, establish a regeneration cycle, and support sustainable and high-quality forest management. Moreover, Komatsu is undertaking reforestation and land rehabilitation initiatives on former mine sites to expand green areas. Our employees are engaged in tree-planting activities not only in North America but also in countries such as China and Indonesia, contributing to local environmental restoration. |

| Product safety and quality risk | |

|---|---|

| Risk description | Komatsu strives to maintain and improve product quality and reliability based on strict internal standards. During both the design and quality verification stages, we anticipate a wide range of potential hazards—not only those that could cause harm to people but also those that could impact property, the environment, and society. We also consider hazards throughout the product lifecycle, from shipment to disposal, and those arising from diverse usage patterns. We implement protection measures such as intrinsic safety design and additional safeguards. However, in recent years, product regulations and standards across various countries and regions have become increasingly stringent. Compliance is now required for a broad spectrum of regulations, including emissions standards, radio certifications for ICT construction equipment, and the EU's Cyber Resilience Act, among others. If our response to such product regulations and standards is delayed, it could result in lost business opportunities. Additionally, in the event of an unexpected accident caused by product defects in design or manufacturing, there is a risk of incurring compensation costs and damaging the Komatsu Group’s reputation and credibility, which may adversely affect its business performance. |

| Impact on business | Under our basic stance of “commitment to Quality and Reliability,” we place the highest priority on ensuring “safety” and “peace of mind” in our quality assurance activities. However, if a serious safety or quality issue were to arise, particularly given our global business operations, it could have a significant impact—such as loss of business opportunities, deterioration of brand image, erosion of customer trust, and reduced market share. Furthermore, product recalls, sales suspensions, and compensation to customers may increase financial burden. In addition to the economic costs, such safety or quality risks could inflict long-term reputational damage, ultimately harming future business opportunities. |

| Risk Mitigation Actions | Komatsu's production framework is structured so that the research and development (design), manufacturing (production), and quality assurance (verification) departments operate independently. This enables mutual oversight and shared quality-related information across departments, thereby strengthening overall governance. From product planning through to development, production, sales, and after-sales service, all departments work in an integrated manner to consistently deliver safe, high-quality products. At each stage of development and production, we evaluate product conformity through multiple review and assessment meetings and implement robust processes to meet defined targets. These initiatives form the foundation of our quality assurance activities aimed at securing “quality and reliability.” Through this approach, we strive to offer environmentally friendly products and services, ensure compliance with international standards and legal regulations, and enhance both customer safety and satisfaction. In addition, we are incorporating safety assistance systems such as collision avoidance through human and object detection, and devices to help prevent tip-over accidents, thereby further enhancing product safety. To address increasingly strict regulations and standards in each country and region, we have established a dedicated Regulatory Compliance Department within our development function. This team manages a regulatory database and promotes systemization of compliance-related tasks. Specifically, regarding engine emissions regulations, we have separated the testing function from the certification and application management function to enhance organizational independence, improve accuracy, prevent misconduct, and strengthen early detection of anomalies. In addition, to stay updated on the latest regulatory developments in each region, we engage external consultants to collect and analyze relevant information. Regulatory personnel are assigned to major overseas sites and work closely with local law firms to strengthen our legal compliance systems. |

| Supply chain risks | |

|---|---|

| Risk description | Under the philosophy of aiming to build a Win-Win relationship with our business partners, who are on an equal footing with us, and encouraging each other, Komatsu evaluates and selects suppliers accordingly. However, if our efforts toward sustainable and responsible procurement are deemed insufficient for any reason within the supply chain, there is a risk that the Komatsu Group’s brand image and credibility may deteriorate. In addition, the Komatsu Group's procurement of parts and materials is affected by fluctuations in raw material markets and energy prices. Sharp increases in the cost of materials such as steel, or energy such as crude oil and electricity, can lead to higher manufacturing costs. Furthermore, shortages of parts or materials, supplier bankruptcies or discontinued production, multilateral trade restrictions, or disruptions in international logistics may hinder timely procurement and production, resulting in reduced production efficiency and lost sales opportunities. Prolonged disruptions in global supply chains, unexpected surges in material or energy prices, and sustained supply shortages also pose risks of adverse impact on the Group’s business performance. |

| Impact on business | In the construction and mining equipment business, Komatsu conducts business with approximately 2,700 primary suppliers worldwide. Establishing strong partnerships with these suppliers is crucial for the company’s business operations. However, if a supplier fails to comply with regulations or address environmental issues, it could disrupt the procurement of raw materials or continuity of production. Procurement from suppliers accounts for a large portion of Komatsu’s manufacturing costs. For major construction equipment such as medium-sized hydraulic excavators, this ratio reaches approximately 90%. Supply chain-related risks are diverse and include the financial and SLQDC conditions of individual suppliers, natural disasters, pandemics, international trade disputes, and export/import regulations. The occurrence of such risks could lead to production stoppages, increased costs, and ultimately result in delivery delays and declines in quality, affecting customer satisfaction. |

| Risk mitigation actions | In 2020, Komatsu formulated the “Partnership Declaration” to promote mutual growth and added value in the supply chain. Through this declaration, the company is strengthening collaboration with business partners and building new partnerships. Since 2022, Komatsu has held price negotiations with all primary domestic suppliers, including auxiliary material manufacturers, to ensure fair procurement pricing. In FY2024, the company continued such negotiations with 1,207 suppliers and made necessary price adjustments. Komatsu plans to maintain annual price negotiations going forward. To ensure proper procurement practices, Komatsu has established a “whistleblowing system for suppliers” to receive inquiries and reports from suppliers, including those related to violations of the Subcontract Act. This enables the company to quickly identify and correct compliance or transactional issues. In response to Japan’s 2024 logistics reforms, Komatsu also set up a “whistleblowing system for drivers”, allowing truck drivers to consult about transportation-related issues. This system enables the company to collect and appropriately address feedback and concerns from external parties. For key suppliers, Komatsu conducts regular risk assessments to visualize potential risks and promote mitigation efforts. Specifically, the company monitors the operating status of members of the Midori-kai on a monthly basis and provides necessary support in response to business conditions. In 2020, Komatsu also declared its commitment to logistics improvement and joined the Ministry of Land, Infrastructure, Transport and Tourism’s “White Logistics” initiative. The company continues its efforts to realize sustainable logistics by reducing driver work hours through modal shifts and optimized unloading layouts, as well as striving for appropriate freight pricing. To strengthen a resilient production and procurement system that can withstand risks of plant damage caused by natural disasters such as heavy rainfall or flooding, Komatsu has implemented global cross-sourcing, allowing for flexible changes to production sites and supply destinations in response to external conditions. The company also employs multi-sourcing by procuring parts from multiple suppliers, thereby building a system capable of maintaining operations during emergencies. In 2023, Komatsu reinforced its Asia Procurement Center and expanded local sourcing in ASEAN and South Asia. To reduce dependency on specific regions, the company is also promoting global multi-sourcing, including parallel ordering from suppliers in multiple regions by utilizing cross-sourcing. |

| Risks associated with talent acquisition and development | |

|---|---|

| Risk description | At our company, we consider talent to be one of the critical management resources that generate new value. Under this belief, we continuously invest in our workforce, aiming for sustainable growth and development of both the company and employees, in alignment with internal and external environmental changes and management policies. However, due to the declining labor force, a decrease in experienced engineers, and a shortage of engineering talent—particularly in key areas such as digital technology and EV-related technology—the competition for talent acquisition is intensifying globally. If we fail to secure these talents as planned or develop employees with the skills required in these specialized fields and secure the capabilities necessary for product research and development, our ability to execute our business plans and achieve sustainable growth could be significantly impacted. |

| Impact on business | Our medium-term management plan is built on three pillars: 1) Co-creating value through innovation, 2) Pursuing growth and profitability, and 3) Transforming the management foundation. As part of the management foundation transformation, we have positioned “attracting and empowering talent to support business growth” as a key initiative. In driving this initiative, it is essential to acquire and develop digital talents, particularly those proficient in areas such as software development. If the acquisition and development of such talent do not proceed as planned, it could impact the execution of the medium-term management plan and the company’s sustainable growth. In progressing our solution business, it is essential to speed up technological innovation by integrating our core technologies with external knowledge through partnerships and M&A. If these do not proceed as planned, it could impact the medium-term management plan and the company's sustainable growth. In a challenging environment for talent acquisition, the retention and development of acquired employees become critical. Without understanding and addressing employee engagement appropriately, there is a risk of increased talent turnover due to declining engagement, affecting the company's sustainable growth. |

| Risk mitigation actions | We promote Diversity & Inclusion to create a workplace where diverse employees can work with peace of mind, fostering an environment conducive to innovation, enhancing individual motivation, and driving cultural change for overall company growth. As part of this, we are improving the ratio of female employees, supporting LGBTQ, and promoting the employment of people with disabilities while disclosing human capital information. With the reconstruction of our headquarters building, we aim to strengthen our functions as an urban innovation center that revitalizes co-creation and collaboration activities, including industry-academia collaboration and open innovation. Additionally, to secure outstanding talent, we position our global headquarters as a key recruitment hub, expanding opportunities to experience Komatsu through new recruitment events and internships utilizing both real and online formats, thereby enhancing our recruitment capabilities. Due to the difficulty in acquiring digital talents, we are advancing internal development. Since 2019, we have been implementing the "AI Talent Development Program" with a unique curriculum to cultivate talents with knowledge and skills in AI, the ability to convert customer business challenges into AI-solvable problems, and the capability to drive projects in collaboration with leading companies. Furthermore, we regularly conduct engagement surveys globally to understand, analyze, and address employee engagement, identifying strengths and challenges by region and organization, and reflecting these insights in HR policies. |

| Information security risk | |

|---|---|

| Risk description | In recent years, cyberattacks have rapidly become more sophisticated and deceptive, posing an increasingly urgent and serious threat. Techniques such as unauthorized access, ransomware, phishing, and DDoS attacks have evolved, and if affected, companies face risks such as operational disruptions and information leaks. These incidents can result in the loss of customer trust, damage to brand value, legal penalties, and an increased risk of litigation, thereby having a significant impact on corporate management. Furthermore, many countries and regions have recently enacted or tightened laws and regulations concerning privacy protection, cybersecurity, and economic security—including personal data protection, cybersecurity enforcement, and data localization. If Komatsu fails to comply with these requirements, it may incur legal liabilities and suffer adverse effects on its credibility, brand image, and relationships with customers. |

| Impact on business | Komatsu is actively engaged in IoT-related businesses such as “connected factories” utilizing ICT, electrified construction equipment, Smart Construction, automation of mining equipment (e.g., AHS), and data-driven solutions (e.g., KOMTRAX). At the same time, however, the growing sophistication of cyberattacks has increased the risk of these systems being targeted. Although we have implemented multiple countermeasures to reduce the risk of unauthorized control, if a cyberattack were to result in a major information leak or system shutdown, our information security measures could be perceived as inadequate. This may lead to suspension of transactions by customers or reluctance to share data, thereby hindering our solution business. In addition, Komatsu operates globally in its construction and vehicle businesses through 62 production bases, 56 sales sites, and 208 dealers and service providers in 151 countries. Should we fail to meet strengthened legal and regulatory requirements in any of these countries or regions, it could result in legal liability due to non-compliance and cause serious damage to our credibility and business performance. |

| Risk mitigation actions | To address these risks, Komatsu has established and operates 19 CSIRTs (Computer Security Incident Response Teams) globally to ensure prompt response, minimize damage, and enable swift recovery in the event of an incident. In FY2023, we also launched a FSIRT (Factory Security Incident Response Team) to handle risks specific to production sites. The FSIRT conducts security monitoring of factory networks and production equipment and implements incident response drills to ensure the continuity of manufacturing operations. In the event of a cyber incident at a factory, the FSIRT works closely with the CSIRT to respond effectively. To continue delivering secure products to our customers, we promote the “Security by Design” approach, embedding security considerations from the product planning and design stages. We are also building systems to manage vulnerability information and establish response processes, aiming to ensure security throughout the entire product lifecycle. In addition, we closely monitor global regulatory trends such as the Cyber Resilience Act (CRA) and the NIS2 Directive, as well as evolving customer requirements, and are working to develop the necessary processes to comply with them. Furthermore, we are enhancing collaboration with dealers and suppliers in our supply chain to promote cyber resilience across the entire Komatsu Group and its value chain. |

| Geopolitical risks | |

|---|---|

| Risk description | Our company operates globally, with development, production, and sales bases in various countries worldwide. Social, political, and military tensions in specific regions can potentially impact our business. We monitor and analyze political and economic conditions, as well as regulatory trends in each country, to minimize the impact of diverse geopolitical risks, such as resource price fluctuations, import/export regulations, and supply chain disruptions. However, with the ongoing global political divisions and rising military tensions, there is a growing risk of supply chain disruptions and impacts on financial and economic stability. In response, we continue to gather and analyze information on the latest developments in economic security-related laws and regulations, including the Economic Security Promotion Act in Japan. Nevertheless, if we face unexpected situations, there remains a risk of adverse effects on our business performance. |

| Impact on Business | Considering the Russia-Ukraine situation, Komatsu has halted shipments of main units, parts, and components to Russia and suspended operations of its production subsidiary in Russia. The business environment in the CIS (including Russia, Belarus, and six non-sanctioned countries) remains uncertain. Continued inability to support customers in these resource-rich Central Asian countries could impact future business. Our electronics-related products incorporate advanced technologies, some of which are subject to export controls under the Export Trade Control Order. While the current impact is minimal, further tightening of regulations could result in lost sales opportunities and hinder service support, affecting our business. |

| Risk mitigation actions | To address such risks, Komatsu has established a flexible production structure known as global cross-sourcing, which allows for the mutual supply of products and components across regions. This system enables us to supply products and parts from optimal locations to each market by considering factors such as foreign exchange fluctuations, production capacity at each site, cost competitiveness, and regional demand trends. In addition, we are strengthening multi-sourcing, which secures multiple procurement sources for the same parts to diversify and mitigate risk. As part of our response to the Russia–Ukraine situation, we established Komatsu Central Asia LLP, a wholly owned subsidiary in Kazakhstan, recognizing the importance of the six non-sanctioned CIS countries located in resource-rich Central Asia. This new company is responsible for sales and service functions in the Central Asian region and is expected to further expand our sales and profitability. We have also set up a dedicated department to monitor changes to the Export Trade Control Order, enabling the prompt collection of information and its timely sharing with relevant business units to ensure appropriate responses. Regarding export controls on advanced technologies, we aim to offset any sales declines by developing markets outside regulated regions, enhancing product differentiation, improving capabilities with long-life modules, and increasing the profitability of the parts business, thereby diversifying and expanding revenue sources. |

| Risks associated with AI utilization | |

|---|---|

| Risk description | The evolution of AI has the potential to change the fundamental assumptions of our business. Its effective utilization is essential to Komatsu’s strategy, which is built on three pillars: (1) Co-creating value through innovation, (2) Pursuing growth and profitability, and (3) Transforming the management foundation. Failure to strategically incorporate AI may result in the loss of new business opportunities and reduced competitiveness of our products and services. |

| Impact on Business | Generative AI is a rapidly evolving field, and there is much public debate about its opportunities and risks. Rather than viewing these changes as threats, we need to see them as opportunities and make effective use of generative AI. If we fail to respond swiftly to these rapid technological changes and improve productivity and efficiency for our company, clients, and agents, it could affect our competitiveness. Conversely, incorrect use of generative AI could lead to information leaks due to the input of confidential information or violations of others' rights. |

| Risk mitigation actions | To strengthen coordination among our global bases and promptly respond to changes brought about by generative AI utilization, we have established a cross-departmental project led by the Chief Technology Officer (CTO). This project ensures we quickly adapt to changes through generative AI utilization. By developing and implementing advanced use cases, we gain knowledge and capabilities in new generative AI technologies and ensure safe implementation. Furthermore, as part of our risk management for generative AI usage, we have established global generative AI usage policies and rules, along with conducting internal training based on these guidelines. This approach ensures we prevent information leaks and rights violations while safely incorporating generative AI into our business. |

Regional risks for FY2024

| Risk related to local communities and Indigenous peoples’ rights | |

|---|---|

| Risk description | As it becomes increasingly important for companies to respect human rights and act responsibly, the emergence of human rights violations in business activities can lead to community backlash, boycotts, social criticism, loss of corporate reputation, business delays or interruptions, and cessation of transactions. In the mining business in particular, customers expect respect for the rights of Indigenous peoples. If Komatsu’s products are used in ways that infringe on those rights, the business could be adversely affected. Moreover, there is a reputational risk of being perceived as a company that lacks sufficient consideration for Indigenous rights. |

| Impact on business | Of Komatsu's revenue of 4.1 trillion yen for the fiscal year ending March 2025, approximately 1.9 trillion yen is derived from mining equipment, meaning that sales from the mining business account for about half of the company’s total revenue. Given this, if our efforts to respect the rights of local communities and Indigenous peoples are insufficient or if we fail to address related issues appropriately, it could lead to decreased sales or slowed growth. Such outcomes may result in significant losses to Komatsu's financial performance. |

| Risk mitigation actions | In 2019, Komatsu established the "Policy on Human Rights," declaring that it would conduct business globally in compliance with international standards for human rights respect. This policy is reflected in the "Komatsu Code of Conduct" and is thoroughly communicated to all employees across the global group. Based on this human rights policy, we continuously identify, prevent, mitigate, and address human rights issues in business activities through due diligence, in collaboration with external experts. In FY2022, we conducted web-based human rights surveys targeting all Group companies both in Japan and overseas, as well as major suppliers. The results were feedbacked to the responding companies, and we are working on risk mitigation measures. In addition, we conducted an impact assessment in the Republic of South Africa, where we engaged in focused discussions on human rights with various stakeholders. These discussions led to meaningful results, including the sharing of challenges and values with customers and a deeper mutual understanding. As part of our stakeholder engagement efforts in downstream business, in FY2024 we held meetings with an independent distributor covering West African countries. These discussions extended beyond human rights to cover a wide range of sustainability-related topics, including environmental initiatives, local talent development, and community contribution activities. Furthermore, Komatsu is working to foster human capital in regions where human resource development has become a societal issue, in collaboration with governments, local authorities, and customers. In our mining business, for example, we are implementing proprietary human resource development programs in countries such as those in South America and the Republic of South Africa. These programs are designed to provide basic education and practical technical training to people who have limited access to educational opportunities due to various national and regional circumstances. Going forward, Komatsu remains committed to respecting the rights of local communities and Indigenous peoples through its global operations, contributing to the realization of a sustainable society. |

Greater political divisions globally may lead to tighter regulations in some countries. The Komatsu Group collects and analyzes information on trends related to the Economic Security Promotion Act and other economic security-related regulations.

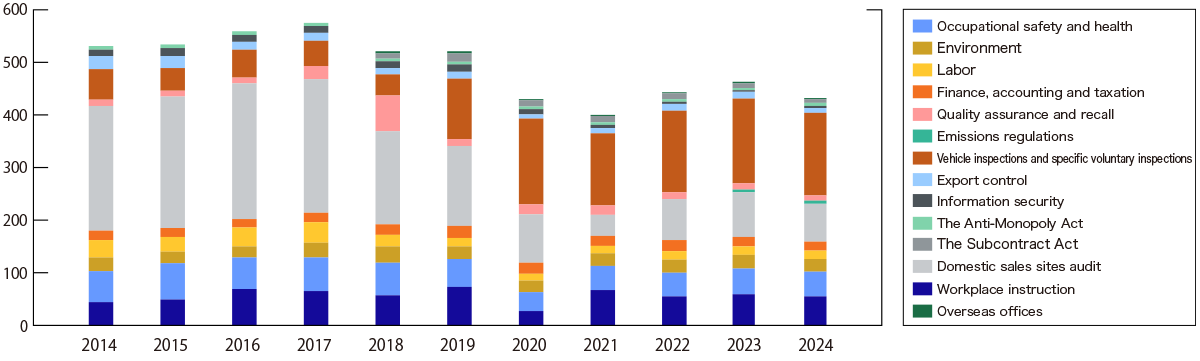

As part of its risk management activities, Komatsu has been conducting compliance risk audits (CR audits) since FY2008. These audits cover areas not included in J-SOX audits, which are conducted in accordance with the Financial Instruments and Exchange Act of Japan to evaluate internal controls related to financial reporting, and are intended to visualize potential compliance risks within the company, with a particular focus on confirming and evaluating the status of legal compliance. Our internal specialist team conducts periodic internal audits (targeting one full cycle every three years), focusing on Komatsu and its Japanese and overseas affiliates, independently owned distributors in Japan, business partners, and domestic distributors. Through these activities, we aim to further enhance the management level and compliance awareness of each company and department. We continually review audit areas and methods to respond to changes in the business environment and strive to improve the quality of CR audits. The status of CR audits is reported monthly to the president and annually to the board of directors.

The audited items in FY2024 are:

1. Occupational safety and health, 2. Environment, 3. Labor, 4. Finance, accounting and taxation, 5. Quality assurance and recall, 6. Emissions regulations, 7. Vehicle inspections and specific voluntary inspections (inspections required by law), 8. Export control, 9. Information security, 10. The Anti-Monopoly Act, 11. The Subcontract Act

In addition, as cross-sectional CR audits covering the above areas, we implement field instruction sessions at each sales company base (Occupational safety and health; Environment; Vehicle inspections and specific voluntary inspections), sales office audits (Finance and accounting, Labor, Information security), and audits of overseas representative offices (Occupational safety and health; Labor; Finance and accounting; Information security).