Occupational safety and health is a core component in Komatsu's business operations. In line with this commitment, Komatsu thus enhances safety at the workplace for our employees and business partners.

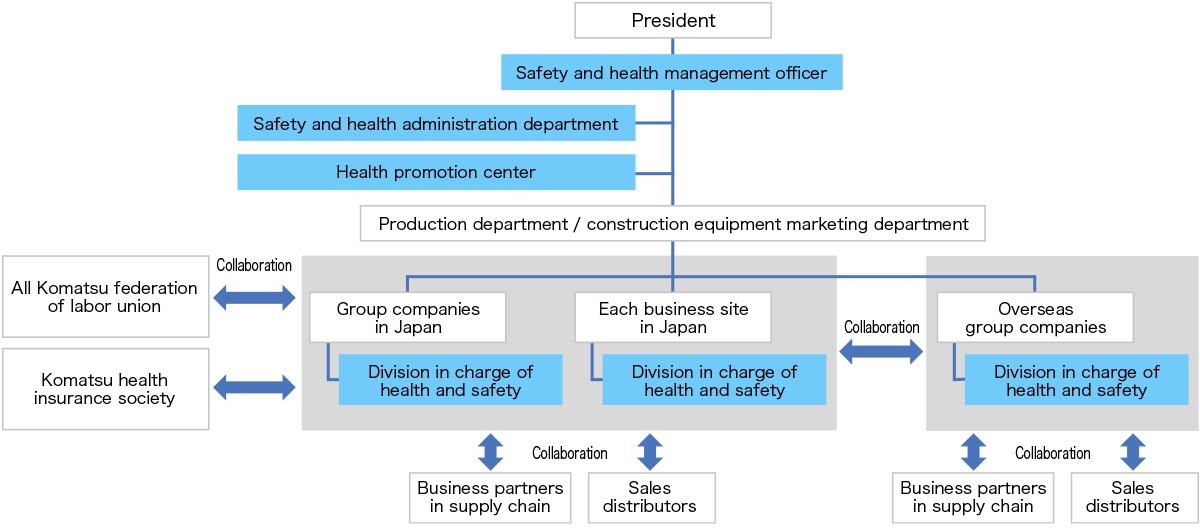

The Komatsu Group promotes safety, health, and health management as per the following structure.

The Komatsu Group holds various meetings to discuss and share information on safety, health, and health management, including the following:

This conference convenes with the aim to increase awareness regarding safety and health for employees of the Komatsu Group and partner companies while raising the level of safety and health activities. It involves sharing activity policies, priority items, and outstanding safety and health activities, and disseminating this information within individual departments. The conference also includes the presentation of presidential awards related to safety and health.

This committee, comprising both labor and management, investigates, deliberates, and decides on fundamental measures to eliminate workplace risks and prevent health hazards.

We shall share and discuss information on safety, health, and the environment in each region globally, leading it to the safe and healthy activities of each overseas subsidiary. In FY2024, we held the conferences in North America, Latin America, Europe, Asia and China.

This committee consists of business owners and employees (organized by Komatsu Union) as well as the Health Insurance Society. This occasion affirms a common recognition of "Health", and formulates measures and policies aimed to enhance the health care for employees and their families.

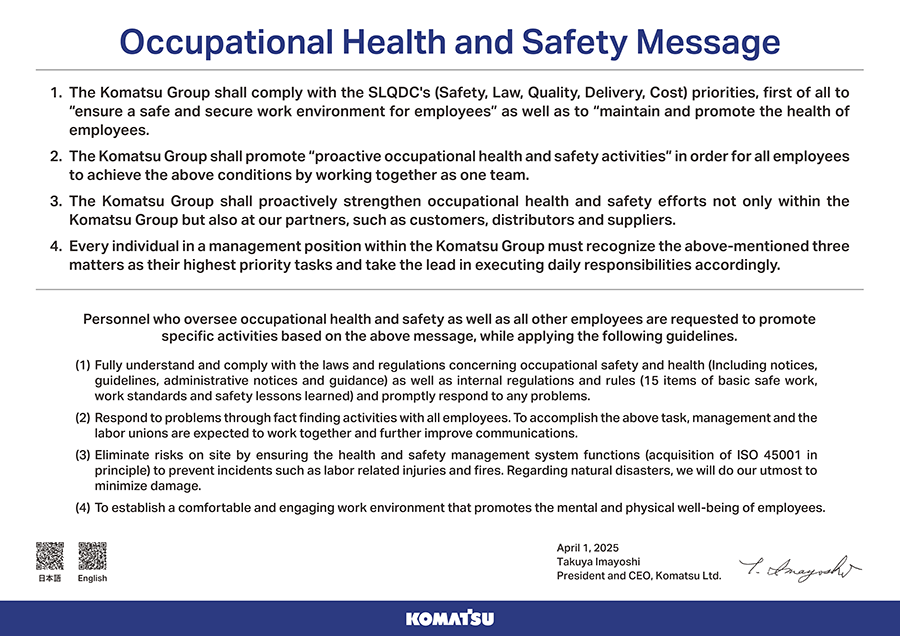

As a guiding principle for employee actions, “Safety & Health, Compliance, Quality, Delivery, Cost” are prioritized, with safety and health taking precedence. Additionally, based on the President’s “Message concerning Occupational Safety and Health,” the entire group is committed to ensuring a safe and secure work environment and promoting the maintenance and improvement of employee health. To achieve this, all employees work together to actively advance safety and health management activities under the established “Safety and Health Policy.”

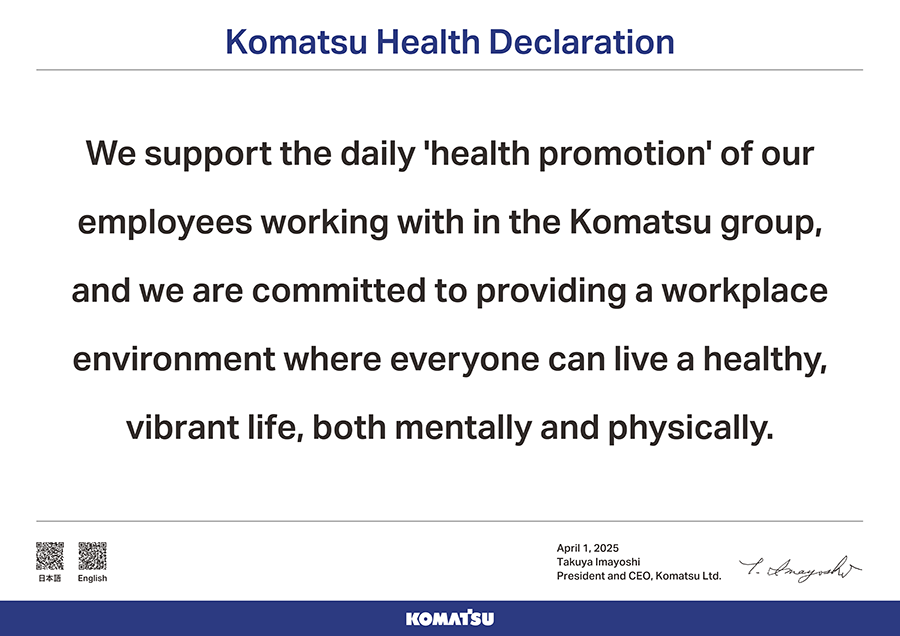

Komatsu’s health initiatives began in earnest in 2014 with the announcement of the Komatsu Health Declaration and the launch of the Five-Year Health Development Plan. This plan was based on the belief that simply “managing” health is not sufficient for employees to lead fulfilling lives both during and after their careers. Instead, it aims to foster a culture of health in which employees are encouraged to pay attention to their own health and that of their colleagues, think critically about what is needed, and take proactive action—this is what we define as health literacy*.

In FY2019, we launched the Second Health Development Plan, which has been actively promoted in the years since. From FY2025, we have begun implementing the Third Health Development Plan, which introduces new initiatives.

In the latter half of the Second Plan, we expanded our efforts beyond the domestic Group to include overseas Group companies as well. As a result, our activities to build a global culture of health are steadily gaining momentum across Komatsu worldwide.

Occupational safety and health policies

We set key activity items and our target values and are promoting the following activities throughout the Komatsu Group.

[Safety and health management]

Major disaster elimination activities

[Health management]

Global Health Management Activities

Improvement of employees’ health literacy

▷ Tobacco-related diseases

▷ Lifestyle improvement

Since FY2014, the Komatsu Group has implemented the Five-Year Health Development Plan to “implement outstanding health management” and “improve employees’ health literacy*.

In FY2019, the Second Health Development Plan was launched to further advance the initiatives of the previous mid-term plan. This plan promoted the development of a lifelong culture of health by enhancing support for work-life balance, strengthening primary prevention (such as improving lifestyle habits), and introducing ICT tools to improve health-related systems and environments.

Starting in FY2025, the Third Health Development Plan will be launched. Building upon the results and challenges identified in the Second Plan and the framework of the Health Management Map, we will continue to advance the creation of a culture of health throughout the company.

Major accomplishments in FY2024 are listed below:

| Item | Initiative | KPI | Result | Goals (FY2025) |

|

|---|---|---|---|---|---|

| FY2023 | FY2024 | ||||

| Improvement of Health Literacy | Enhancing the ability to acquire, understand, select, and utilize accurate health information necessary for individuals to engage in proactive health behaviors | Communicative and Critical Health Literacy Scale*1 | 3.55 | 3.55 | 3.7 or higher |

| Cancer and lifestyle diseases | Increase the percentage of employees using the various health checkup consultations for the early detection and treatment of cancer and lifestyle diseases and the prevention of severe diseases | Regular check-up percentage | 100% | 100% | - |

| (Reference) Secondary health check-up percentage | 98.9% | 97.3% | 100% | ||

| Milestone checkup consultation percentage | 84.4% | 86.3% | 95% or more | ||

| Female cancer checkup consultation percentage | 58.2% | 56.6% | 80% or more | ||

| Tobacco-related diseases | Reduce secondary exposure to cigarette smoke and smoking percentage | Percent of the Komatsu Group in Japan that smokes | 28.5% | 26.1% | Not more than the national average of smokers (16.7%) |

| Lifestyle improvement | Establish a system or environment that leads to the improvement of motivation to improve or promote the healthy lifestyles of employees (e.g. diet and exercise) | Percent of employees with Healthy Action Competency*2 | 53.8% | 54.7% | 60% or more |

| Mental health | Reduce the number of individuals with mental disorders, provide early care, appropriately support their return to workplaces, and create a happy and vigorous workplace | Percentage responding to our recommendation to interview employees under high stress | 97.7% | 99.4% | 100% |

| (Reference) Stress check implementation percentage | 98.6% | 99.0% | - | ||

| Percentage responding to high-stress workplaces | 100.0% | 100.0% | 100% | ||

(Scope of aggregation: All employees of the Komatsu Group in Japan)

*1 The figures are calculated based on the average score out of 5 for the five questions in the questionnaire (1. Information collection, 2. Information selection, 3. Understanding and communication, 4. Reliability assessment, 5. Planning and action).

*2 Capability of voluntarily practicing healthy actions (lifestyle improvement/maintaining an appropriate exercise regimen and diet, etc.)

| Item | Initiative | Result | ||

|---|---|---|---|---|

| FY2023 | FY2024 | |||

| Absenteeism | Average number of days lost per employee per year due to mental health issues | 1.52 days/year | 1.59 days/year | *3 |

| Presenteeism | Evaluate one's own work performance over the past four weeks, assuming 100% performance when there is no illness or injury Presenteeism = 100 - Average score of all employees |

14.8% | 15.2% | *4 |

*3 FY2023: Number of subjects: 23,028 people FY2024: Number of subjects: 22,248 people

*4 FY2023: Number of participants: 21,334 people (response rate: 98.5%) FY2024: Number of participants: 21,402 people (response rate: 99.2%)

As part of the "Lifestyle Improvement Promotion" of the "Second Health Promotion Plan," in FY 2021, we launched the Komatsu Health Promotion 100 (KHP100) in cooperation with the Komatsu Health Insurance Association to further promote employees’ health and health literacy.

Under KHP100, we distribute wearable devices to employees who wish to use them to visualize their physical activity and exercise. We also offer walking and other health events on a health portal that can be linked to the device, providing employees with opportunities to change their health-related behavior.

Komatsu has been certified as a “Sports Yell Company 2025” by the Japan Sports Agency in recognition of its initiatives such as KHP100, which aim to promote employee health. This marks the second consecutive year Komatsu has received this award, following its first in 2023.

The "Sports Yell Company" is a system that recognizes companies that are actively engaged in promoting sporting activities to enhance employees’ health, encourage hard-working people to play sports, and foster social momentum for sports.

For details on the safety activities for the member companies of Midori-kai, an organization made up of our business partners (suppliers), please click "Support for Member Companies of the Komatsu Midori-kai" .

Komatsu published its first Health & Well-being Report in July 2025, with the aim of introducing and disclosing its health-related initiatives and data both internally and externally, thereby raising awareness and enhancing employee consciousness around health and well-being. The report outlines Komatsu’s objectives, policies, and progress in promoting health and well-being, along with related initiatives, achievements, and data. Going forward, we plan to publish the report regularly in line with the progress of our health promotion plans.

| Contents | FY2024 Practice |

|---|---|

| Based on the rules of the Industrial Safety and Health Act, educational training for mental health is conducted. Stress tests were started in FY2006, and stress awareness training were started in FY2007 and is being held for the employees of all Group companies in Japan. |

|

| Contents | FY2024 Practice |

|---|---|

| Safety and Health education and mental health education is provided to each level of Komatsu Group companies in Japan including new employees. | New employees (351 people)* Third-year / Seventh-year employees (292 people) Mid-career recruitment (119 people) New assistant managers (365 people) Foremen/senior foremen (45 people) Assistant Foremen (45 people) New managers (244 people) |

| Contents | FY2024 Practice |

|---|---|

| Safety and health education is provided according to function to the production managers, Production Engineering Division, and workplace safety and health promotors of Komatsu group companies in Japan. | Safety and health practical training for production managers (21 trainees) Education for production engineers (55 trainees) ISO 45001 standards understanding training (46 trainees) ISO 45001 internal auditor development training (113 trainees) ISO 45001 internal auditor level-up training (34 trainees) |

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | ||

|---|---|---|---|---|---|---|

| Komatsu group consolidated companies | Subtotal | 3 | 0 | 2 | 0 | 0 |

| Japan | 0 | 0 | 0 | 0 | 0 | |

| Overseas | 3 | 0 | 2 | 0 | 0 | |

| Non-consolidated sales companies | Subtotal | 1 | 0 | 0 | 0 | 0 |

| Japan | 1 | 0 | 0 | 0 | 0 | |

| Overseas | 0 | 0 | 0 | 0 | 0 | |

| Contractors | Subtotal | 1 | 0 | 1 | 0 | 0 |

| Japan | 0 | 0 | 0 | 0 | 0 | |

| Overseas | 1 | 0 | 1 | 0 | 0 | |

| Total | 5 | 0 | 3 | 0 | 0 | |

The Komatsu Group thoroughly analyzes the causes of each incident and shares preventive measures across all relevant operations to prevent recurrence.

We take these accidents very seriously, and will continue to actively engage in appropriate safety and health activities to ensure that such accidents will not occur again.

Since FY2007, in Japan, the Komatsu Group has taken steps to acquire or renew OSHMS certification at each business site and has been working to obtain ISO 45001 integrated international standards certification since FY2018. The Osaka Plant acquired ISO 45001 integrated international standards certification for the first time in April 2019 and other divisions and Group companies acquired this certification in April 2020. We have also taken steps to acquire or renew OHSAS 18001 certification for our overseas facilities and have been working to obtain ISO 45001 certification since FY2018.

ISO 45001 certification requires the following activities to be properly managed by the company's occupational safety and health management system:

| Certified business locations* | First year of certification | |

|---|---|---|

| Komatsu | Osaka Plant | 2019 |

| Head Office | 2020 | |

| Awazu Plant | ||

| Kanazawa Plant | ||

| Ibaraki Plant | ||

| Oyama Plant | ||

| Tochigi Plant | ||

| Koriyama Plant | ||

| Shonan Plant | ||

| Himi Plant | ||

| Shiga Plant | ||

| Field Testing Department | ||

| Group Company | GIGAPHOTON | |

| KELK | ||

| Komatsu NTC | ||

| KOMATSU LOGISTICS Head Office | 2022 | |

| Komatsu Safety Training Center Ltd. | 2024 | |

| Komatsu Customer Support Co., Ltd. | ||

| Certified business locations* | First year of certification |

|---|---|

| Komatsu Chile SA | 2018 |

| Komatsu America Chattanooga Manufacturing Operation | 2019 |

| Komatsu America Newberry Manufacturing Operation | |

| Komatsu UK | |

| Komatsu Italia Manufacturing | |

| Hensley Lingfeng Co., Ltd. | |

| Bangkok Komatsu Co., Ltd. | |

| Komatsu America Peoria Manufacturing Operation | 2020 |

| Komatsu Mining Peru | |

| Komatsu Mining Wadeville | |

| Komatsu Mining Tianjin | |

| Komatsu Germany (Construction Division) | |

| Komatsu Germany (Mining Division) | |

| PT Komatsu Indonesia | |

| PT Komatsu Undercarriage Indonesia | |

| Komatsu Shandong Construction Machinery Corp. | |

| Komatsu Mining Longview | 2021 |

| Hensley Industries, Inc. | |

| Komatsu Changzhou Construction Machinery Corp. | |

| Komatsu (Shuozhou) Remanufacture Ltd. | |

| Komatsu Dalian Machine Tool | |

| Komatsu do Brasil Ltda. | 2022 |

| DESARROLLOS TECHNOLOGICOS S.A | |

| Komasu Manufacturing Rus LLC | |

| Komatsu South Africa (Remanufacturing center) | |

| Distribuidora Cummins Chile S.A. | |

| PT Komatsu Marketing and Support Indonesia | 2023 |

| Komatsu Australia Pty Ltd. | 2024 |

| Komatsu Brasil International Ltda. (KBI) | |

| Komatsu Colombia S.A.S |