Procurement from business partners accounts for a substantial percentage of our production costs, reaching nearly 90% for medium-sized hydraulic shovels, a typical piece of construction machinery. Therefore, for the stable continuation of our business activities, it is essential to identify and respond to risks in our supply chain at an early stage. There are a wide range of risks in the supply chain, including the management of business partners, their SLQDC status, natural disasters, pandemics, international trade conflicts, and import/export regulations. Komatsu visualizes risks through regular risk assessments that we conduct, particularly for critical suppliers, and we are carrying out activities to mitigate those risks. In the construction machinery industry, the market has been in a downturn since the second half of 2023. Komatsu monitors the load status of Midori-kai companies in Japan on a monthly basis, closely observing the impact on each company's management and providing necessary support. Starting in 2024, the overtime work limit regulations will also apply to the transportation industry, raising concerns about a nationwide shortage of transportation capacity. In 2020, Komatsu announced its declaration of voluntary action to improve logistics based on mutual understanding and cooperation with suppliers and logistics companies, and joined the "White Logistics" promotion campaign by the Ministry of Land, Infrastructure, Transport and Tourism. We are continuously working towards sustainable logistics by reducing long-distance transportation through the use of modal shifts, optimizing loading and unloading area layouts to reduce driver working hours, and striving to set appropriate freight rates.

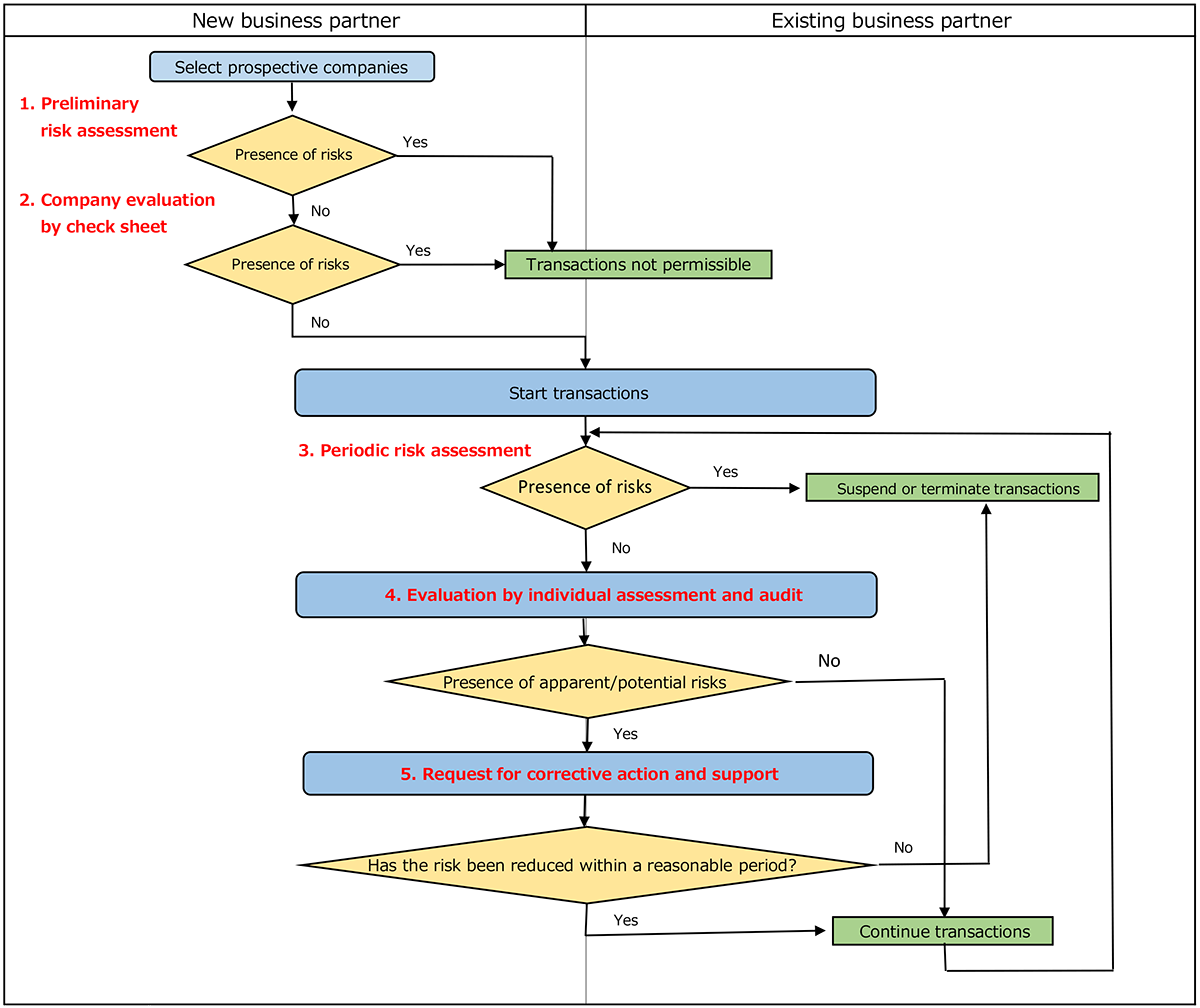

When determining whether to start a business with a new business partner, we conduct a preliminary evaluation of the company by researching public information, performing interviews, and conducting on-site audits. We also utilize the new supplier evaluation checklist to assess both the basic SLQDC criteria and ESG aspects of the company.

Compliance with the aforementioned CSR Procurement Guidelines and understanding of the Green Procurement Guidelines are also included in the evaluation items, with the highest weighting assigned to ESG-related categories. We prioritize procurement from business partners with high ESG performance.

Suppliers with an ESG score below 50% are excluded from contracting.

Weight of points for new supplier evaluation by item

| Category | Evaluation item | Weight (%) |

|---|---|---|

| ESG | Occupational health and safety, environment, compliance, export control, information security | 27% |

| General management | Management policy, organization, financial structure, employee training, etc. |

24% |

| Production capacity | Production planning to progress management and delivery management system, procurement ability, and outsourcing management | 20% |

| Technical superiority | Development capability, cost efficiency, and maintenance ability, etc. | 16% |

| Quality |

Assurance system, on-site management, initial product management, etc. |

12% |

| Total | 100% | |

We conduct regular risk assessments using specialized external databases to screen new and existing business partners for compliance purposes. This process includes verifying whether business partners are associated with high-risk customers, regulated countries, regulated items and technologies in terms of export control, and whether they have any connections with or involvement in anti-social forces. We utilize public information and quarterly surveys to evaluate the financial and management status of potential suppliers. If companies of concern are identified, we employ credit reporting agencies to conduct further verification. In terms of CSR and ESG, we regularly verify compliance with occupational health, environmental laws and regulations, antimonopoly acts, subcontracting laws, and immigration acts through government agencies and related local authorities' websites. As part of our risk management processes for raw material procurement in the construction machinery industry, we also continue to conduct investigations on the countries of origin of conflict minerals.

Risk assessment process for business partners

Key risk assessments and implementation status for suppliers

| Category | No | Objective | Content | Measures to check | Frequency | Target (○ to be implemented) | Implementation status in FY2024*1 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Critical suppliers (Tier 1 suppliers only) | Other Tier 1 suppliers | Number of companies | Number of companies subject to individual follow-up | Number of companies with completed or planned corrective actions | ||||||||||

| Level-1 | Level-2 | Level-3 | Japan | Overseas | ||||||||||

| Compliance | 1 | Determine companies of concern for export control. | Check whether the company falls under or is related to the list of companies of concern published by Japanese and overseas government agencies. | Chaser search in the CISTEC database. | Once a year | 〇 | 〇 | 〇 | 〇 | 〇 | 2,148 | 0 | - | |

| 2 | Determine association with anti-social forces. | Check whether the company falls under or is related to anti-social forces. | Verify through public information and specialized agencies. | Twice a year | 〇 | 〇 | 〇 | 〇 | 2,207 | 0 | - | |||

| Management | 3 | Confirm management status. | Credit investigation | Confirm management and financial status. | Public financial information and reports from private credit investigation agencies. | As needed | 〇 | 〇 | 〇 | 〇 | 〇 | 2,207 | 0 | - |

| 4 | Periodic survey of business conditions | Surveys on profit and loss, employment, operation rate, investment, and overall management. | Questionnaires | Quarterly | 〇 | 〇 | ||||||||

| ESG | 5 | Check for violations of labor, environment, antitrust, subcontracting, immigration, and other laws and regulations. | Search for cases of violations announced by the Labor Standards Bureau, local governments, Japan Fair Trade Commission, Immigration Bureau, etc. | Monthly | 〇 (Japan) |

〇 (Japan) |

〇 (Japan) |

〇 | 2,207 | 0 | - | |||

| BCP | 6 | Identify any risk of natural disasters (flooding, tsunami, landslide, etc.) based on business location. | Check hazard maps published by the Ministry of Land, Infrastructure, Transportation and Tourism, and Aqueduct. | Once every 3 years | 〇 | 〇 | 〇 | 〇 | 〇 | 1,326 (Japan) |

0 | - | ||

To address the potential risks identified in the supply chain, Komatsu conducts risk assessments and audits, in addition to the previously mentioned assessments, based on the importance of our business partners. These risk assessments and audits, conducted by our experts, cover individual areas of business activities. They are carried out through both desktop surveys and on-site surveys. The table below outlines the content, scope, and implementation status of these assessments and audits in FY2024.

We report apparent and potential ESG risks identified through these risk assessments and audits to our business partners, request them to develop corrective plans, and implement appropriate measures within a reasonable period. If it is difficult for the partners to address these issues independently, Komatsu provides guidance and support, with our experts assisting upon request. In FY2024, we supported 21 companies. No business partners were terminated due to significant negative impacts resulting from these risk assessments, audits, and corrective actions in FY2024.

The status and results of these processes, especially concerning significant risks, are reported regularly to our management by the Procurement Division through monthly reports, including the details and progress of corrective measures.

We then incorporate the results of these assessments and audits into our purchasing policies to maintain consistency between our supplier code of conduct and purchasing activities.

In parallel with these individual corrective activities, we continue to support our partners in improving their overall understanding and response capabilities in CSR activities by providing various educational and training programs for employees, as well as publishing and offering e-learning resources.

In FY2024, we provided human rights education to approximately 500 employees.

We also recommend obtaining official certification from external third-party organizations to enhance environmental management and health and safety activities.

Major individual risk assessments and audits of business partners

| Category | No. | Content | Measures to check | Freuency | Target (○ to be implemented) | Implementation status in FY2024 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Critical suppliers (Tier 1 suppliers only) | Other Tier 1 suppliers | Number of companies | Number of companies with corrective action plans formulated | Completed corrective actions | |||||||||

| Level-1 | Level-2 | Level-3 | Japan | Overseas | |||||||||

| General | 1 | Strengthen interactive communication through Midori-kai activities | (1) Interaction among company leaders at regular meetings. | Meeting | Twice a year | 〇 | 〇 | 〇 | 334 | - | - | ||

| (2) Promote activities to improve productivity, energy conservation, etc. through subcommittees. | Plant visit, activity briefing, etc. | all-year | 219 | - | - | ||||||||

| Management and QCD | 2 | Corporate evaluation | Evaluate annual SLQDC and ESG performance | KPI result | Annually | 〇 | 〇 | 〇 | 334 | 0 | 0 | ||

| Evaluate the factor about the above and corporate management | KPI result, management interview | 〇 | 〇 | 98 | 0 | 0 | |||||||

| 3 | Quality audit and heat treatment audit (only for companies with safety parts and heat treatment processes) | Confirm quality assurance system and process control status. | Written survey, onsite audit, voucher check, etc. | Annually (designated companies) | 〇 | 〇 | 〇 | 〇 | 〇 | Heat treatment audit 337 |

0 | 0 | |

| 4 | Monthly operation capacity check | Confirm monthly operation capacity forecast and the way to forecast. | Written survey, management interview | Monthly | 〇 Japan |

〇 Japan |

165+α*1 | 0 | 0 | ||||

| Compliance and ESG | 5 | Compliance risk (CR) audit on important process | Identify potential risks in the areas of accounting and finance, labor management, procurement (subcontracting law), and information security. | Written survey, onsite audit, voucher check, etc. | Once every 2 years | 〇 | 4 | 2 | 2 | ||||

| 6 | Survey on the employment status of overseas workers | Survey on compliance with laws and regulations regarding employment of overseas workers (including trainees). | Questionnaire and interview | Annually | 〇 | 〇 | - | - | - | ||||

| 7 | Occupational health and safety level assessment (including compliance check) | Confirm organizational structure to promote occupational safety and health activities, compliance with labor-related laws and regulations, and evaluation of activities. | Onsite audit such as safety patrol, interview with management and safety managers, etc. | Twice a year | 〇 | 〇 | 98 | 15 | 15 | ||||

| 8 | Promote acquisition of environmental management system (EMS) and environmental education | Mandate acquisition of third-party certification for environmental management | Written survey, onsite audit, Interview with management and environmental officers, etc. | Annually | 〇 | 〇 | 〇 EMS |

98 | 0 | 0 | |||

| Implemate education on the latest environmental laws and regulations | Online education | Annually | 〇 | 〇 | 98 | 4 | 4 | ||||||

| 9 | CSR SAQ survey | Self-assessment of overall CSR using a checklist. | Questionnaire and interview | Once every 3 years | 〇 | 〇 | 〇 | - | - | - | |||

| 10 | Risk survey on human rights | Self-assessment focused on human rights and occupational health and safety using a checklist. | Once every 2 years | 〇 | 〇 | 〇 | - | - | - | ||||

Examples of corrective action support for business partners

| Category | No. | Major support | Content |

|---|---|---|---|

| Management | 1 | Cash management support | Advance payment, cash payment, etc. |

| Purchase of excess inventory, advanced ordering & receiving, etc. | |||

| Purchase of production equipment, lending, etc. | |||

| 2 | Human resource support | Dispatch of managers and technical instructors on secondment, acceptance of training at our company, etc. | |

| 3 | Provision of education and training programs | For managers and general employees |

At Komatsu, we launched a whistleblowing system for suppliers in March 2017 to accept whistleblowing reports from suppliers on acts in procurement activities of the Komatsu Group which are violating or alleged to be violating laws and regulations. Matters reported via dedicated contacts, which we set up inside and outside the company, are handled by a department in a neutral position. This department investigates and verifies facts to take corrective measures promptly. We have pledged to ensure that business partners who submit whistleblower reports do not receive disadvantageous treatment because the report has been made.

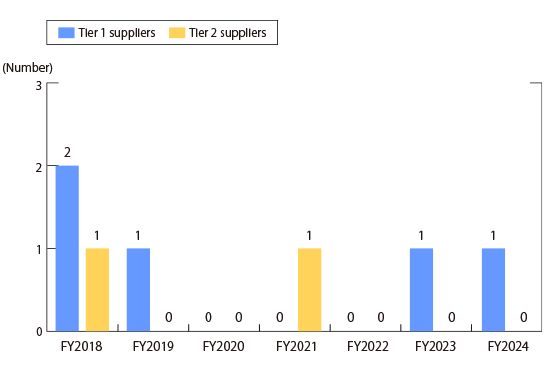

Changes in reported cases

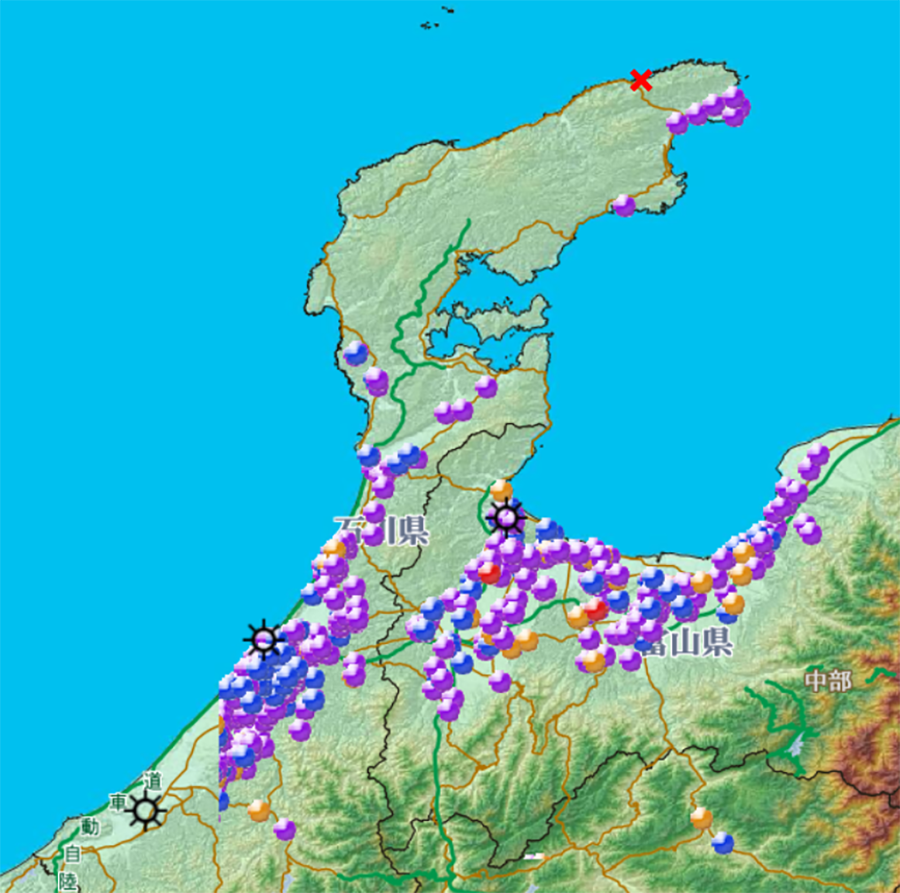

To respond to the increasingly frequent and diverse natural disasters in recent years, we have been operating a supply chain management system in Japan linked to disaster information from the Japan Meteorological Agency since 2012. This system aims to quickly assess the impact of natural disasters, such as earthquakes, tsunamis, and typhoons, on our business partners and our supply chain. We have built a database of locations and production details for over 20,000 sites managed by 7,662 business partners, including secondary and subsequent suppliers, thereby visualizing the risks of supply disruptions caused by disasters and enabling us to take prompt and targeted actions. During the Noto Peninsula earthquake on January 1, 2024, this system allowed us to quickly check the status of affected business partners and, where support was requested, dispatch building and equipment maintenance personnel from Komatsu to assist in rapid disaster recovery.

In 2019, our supply chain was greatly impacted by the flooding of rivers caused by Typhoon Hagibis (No. 19), which damaged multiple business partners. In light of this, we linked the Komatsu supply chain management system to the hazard maps released by the Ministry of Land, Infrastructure, Transport and Tourism to understand in advance the potential location-related risks faced by our business partners. We have taken measures for our business partners with location-related risks; for example, backing up to store welding and processing programs and important production data (BOM, tooling lists, production drawings, jig and tool drawings, etc.), and building up safety stock and securing alternative suppliers in response to the BCP status of each company.

In addition, since 2020, the global supply chain has been severely disrupted due to the shortage of semiconductors in a wide range of industries, COVID-19 lockdown, US-China decoupling and disruptions in international logistics. Moreover, the reduction in model changeover periods in automobiles and home appliances has increased the risk of sudden production discontinuation of construction machinery parts, especially electrical and electronic parts. We have addressed these emerging risks by strengthening inventory management including at the distribution stage, promoting replacement with stably available general-purpose semiconductors and parts, expanding the scope of pre-orders and forecasts for critical parts, accumulating inventory, and adopting alternative components. We are expanding our Asian Procurement Center to further increase local procurement in ASEAN member countries and South Asia in 2023. We are also promoting multi-sourcing policy, even in cross-sourcing activity (placing concurrent orders with suppliers in multiple regions), to reduce the risk of over-reliance on procurement from a specific region.

Information security measures in the supply chain are also an urgent issue. In 2021, Komatsu established information security guidelines for business partners to clarify the standards we require of our suppliers. We also provided e-learning education to 155 Midori-kai companies in Japan. At the same time, we conducted security assessments using self-check sheets, and followed up individually with suppliers where issues were identified. Starting in 2024, we have also begun recommending and promoting the implementation of Endpoint Detection and Response (EDR) solutions—which include behavior-based threat detection—to Midori-kai subcontractors in Japan, further strengthening security measures across the entire supply chain.

Implementation status of information security self-check

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Number of companies implementing self-check sheets | 156 | 156 | 155 |

To raise our business partners' awareness of Komatsu's CSR procurement guidelines, we are carrying out awareness building activities around Compliance and BCP at the Komatsu Midori-kai meetings and monthly business meeting held in each office. In addition, "CSR Report" issued for Midori-kai member companies shares CSR-related "Everybody's Compliance" articles which are published for the employees of the Komatsu Group, and information regarding the revision of related laws and regulations in Japan and other countries.

To ensure the further penetration of CSR in the supply chain, from FY2021 onward, we have conducted an SAQ survey on CSR activities using the standard survey tool released by the Global Compact Network Japan (GCNJ), of which Komatsu is a participant. The survey targeted 156 Midori-kai companies in Japan, and responses were received from 153 companies. Through this survey, we confirmed that 95% of the responding companies were aware of our CSR Procurement Guidelines.

Moreover, in FY2022, as part of our human rights due diligence, we conducted a human rights risk survey across a total of 292 Midori-kai companies in Japan and overseas. Based on the UN Guiding Principles on Business and Human Rights and other international norms, we collected responses on a dedicated website regarding the status of human rights initiatives in 11 categories, including human rights management, occupational safety and health, and working conditions. To ensure objectivity, the entire survey process from question formulation to results analysis was conducted and overseen by outside experts. We prepared company-specific reports translated into the respective local languages, outlining the issues identified through the assessment and the corresponding responses, and provided individual feedback.

In FY 2023, we visited five companies in the domestic Midori-kai and conducted interviews and discussions with external experts to develop human rights guidelines for our business partners. Based on the feedback from each company, we will reflect their input in the guidelines.

In FY2024, under the guidance of external experts, we carried out preparatory activities to address disclosure requirements and due diligence expectations, particularly in Europe.

Questionnaire items

| No | Themes | Questionnaire items |

|---|---|---|

| 1 | Human rights management | Commitment to human rights, establishing human rights due diligence system, complaint handling mechanisms |

| 2 | Work environment and human rights | Prohibition of discrimination and inhumane treatment, prohibition of child labor and consideration for young workers, prohibition of forced labor Employment and labor relations, personal information protection, proper management of working hours, welfare, wages, respect for workers' rights to organize |

| 3 | Occupational health and safety | Occupational health and safety policies and management, workplace safety measures and environmental improvements, measures to address workers' health risks |

| 4 | Community impact | Impact on the community |